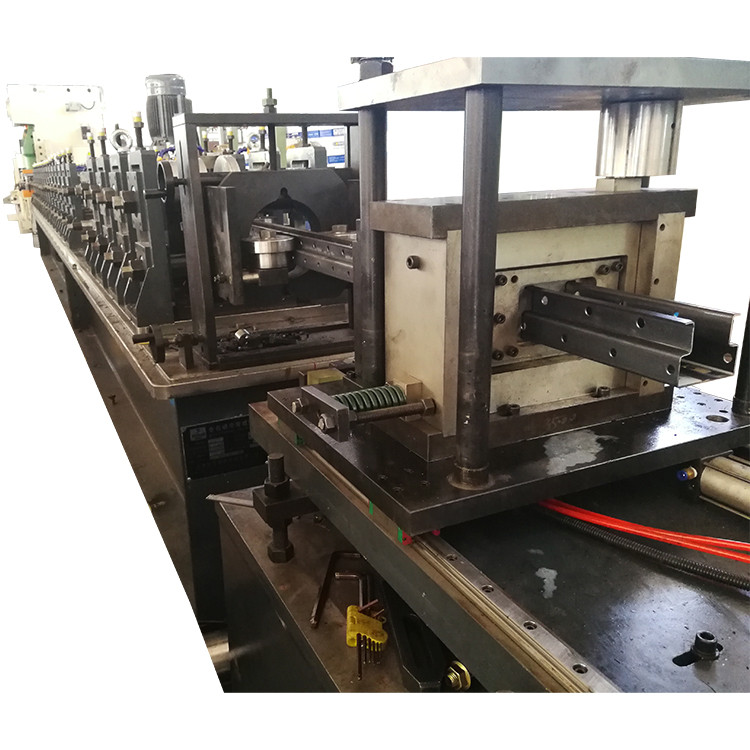

Warehouse shelf upright rack roll forming machine

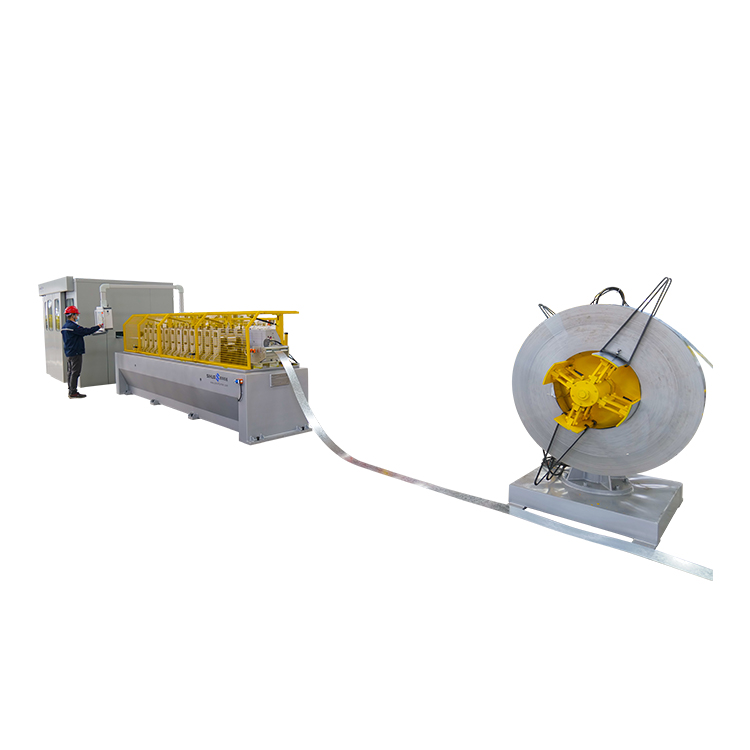

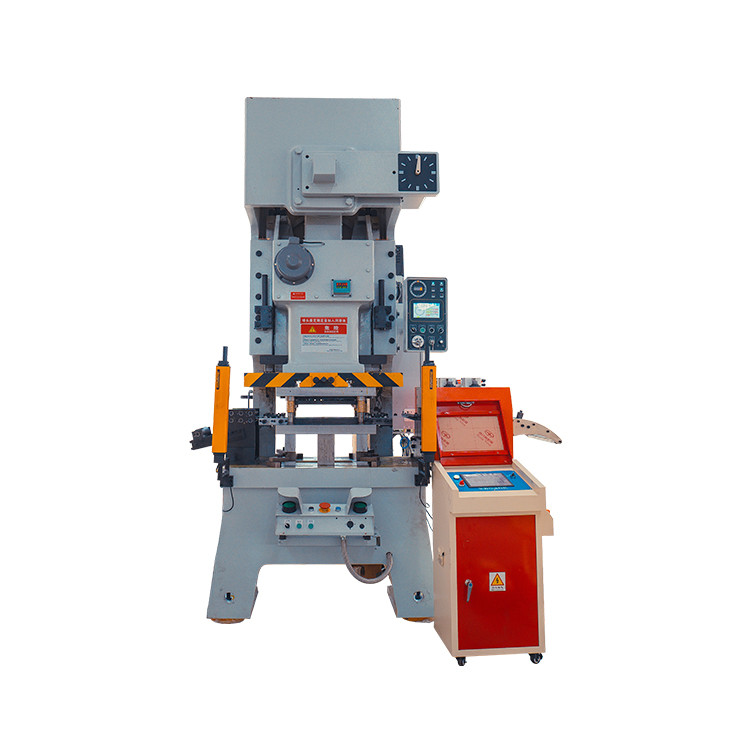

Upright rack roll forming machine is a type of roll forming machine used to produce the uprights, which are one of the main components of pallet rack systems and warehouse shelf systems. The machine uses roll-forming technology to form sheet metal into the desired post profile. The process typically involves automatic uncoiling of the raw material, leveling and feeding through the machine, continuous punching, forming the metal into the desired shape, cutting it to length, and unloading the finished product.

1. Upright rack roll forming machine is widely used in the production of heavy and light columns.

2. This machine can process the thickness of 2.0-4.0mm cold rolled steel, galvanized coil, carbon steel.

3. The machine includes uncoiler, leveling device, punch (according to speed),forming machine, positioning cutting device, frequency converter to control the motor speed, PLC system to automatically control the length and quantity.

4. The machine axis diameter can be 70mm, 80mm, 90mm, through the cassette roller set to replace.

An upright rack roll forming machine is a specialized type of roll forming machine used to manufacture storage racks commonly found in warehouse and industrial settings. The machine operates by feeding strips of metal into sets of rollers that gradually shape the metal into the desired profile, producing components such as columns, box girders and horizontal supports. These components are then assembled together to form tall, sturdy storage racks capable of carrying heavy loads.

Upright rack roll forming machines typically use high-strength steel coils as raw material, which are cut and formed into individual components of consistent quality and precision. Roll forming technology can produce these parts quickly and efficiently, allowing manufacturers to meet demand while minimizing waste and cost.

Overall, upright rack roll forming machines occupies an important position in the manufacture of storage shelves and is widely used in the industry.