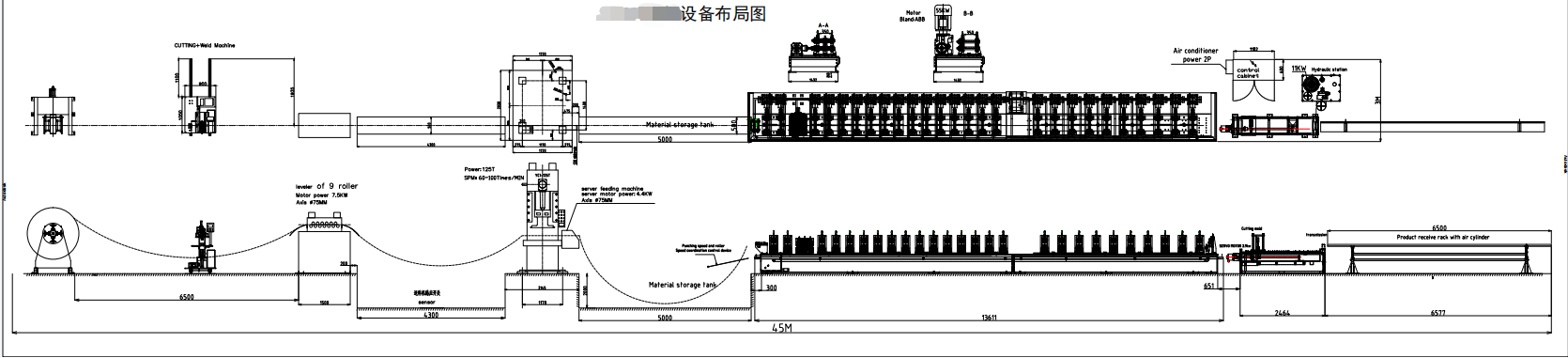

Technical agreement of upright profile production line

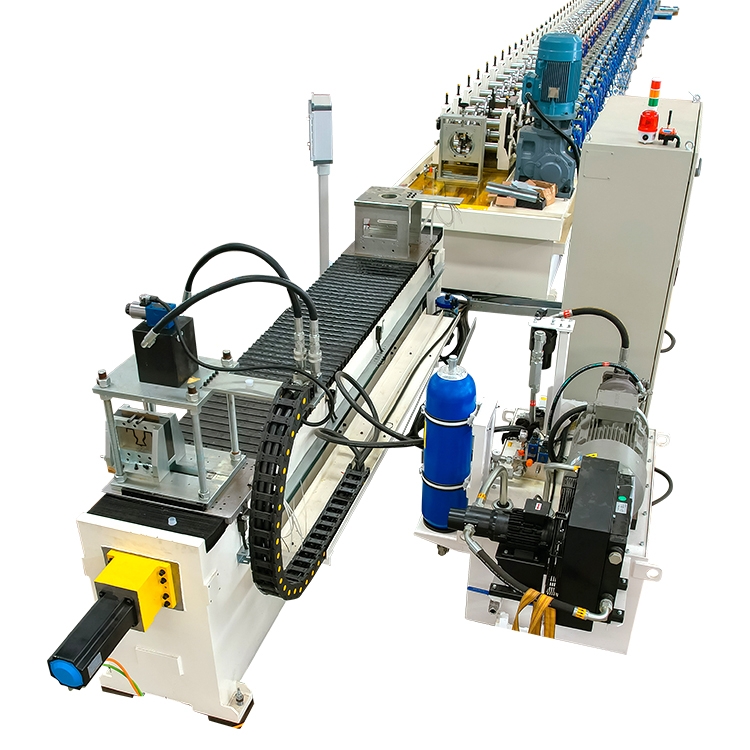

Production process:De-coiler → lever →feeder→punching hole →roll forming profile

→Hydraulic shearing cutting unit →packing table (hydraulic system given power) all parts were control by electrical control system

Un-coiler with hydraulic decoiler with coil wagon

oil internal Diameter stretch range: ∮470-570mm

coil inside diameter:508mm

Max of Coil outside diameter is 2000mm

Hydraulic expansion uncoiler, single headload1*5-6 tons,

Max material width is 400mm

Material width《400MM

Material thickness;3mm

Motor:4.4kw

Up 3 roller

Down 4 roller

Feed pitch accuracy is +-0. 15mm

PLC Brand is Mitsubishi

Servo motor brand is YASKAWA power is 2.9kw

Frequency:70-100times/min

Press machine capacity 250ton

brand :Yadon

Material :Cryodur2990 (German)

250MM steps punching

10sets:

CTEM90 [Profile D]: 1 punching die

CTEM100 [Profile E]: 1 punching die

CTEM120 [Profile F]: 1 punching die

CTES100 [Profile G]: 1 punching die

CTES120 [Profile H]: 1 punching die

CTES140 [Profile I]: 1 punching die

MTA100 [Profile J]: 1 punching die

CTEM80 profile 1

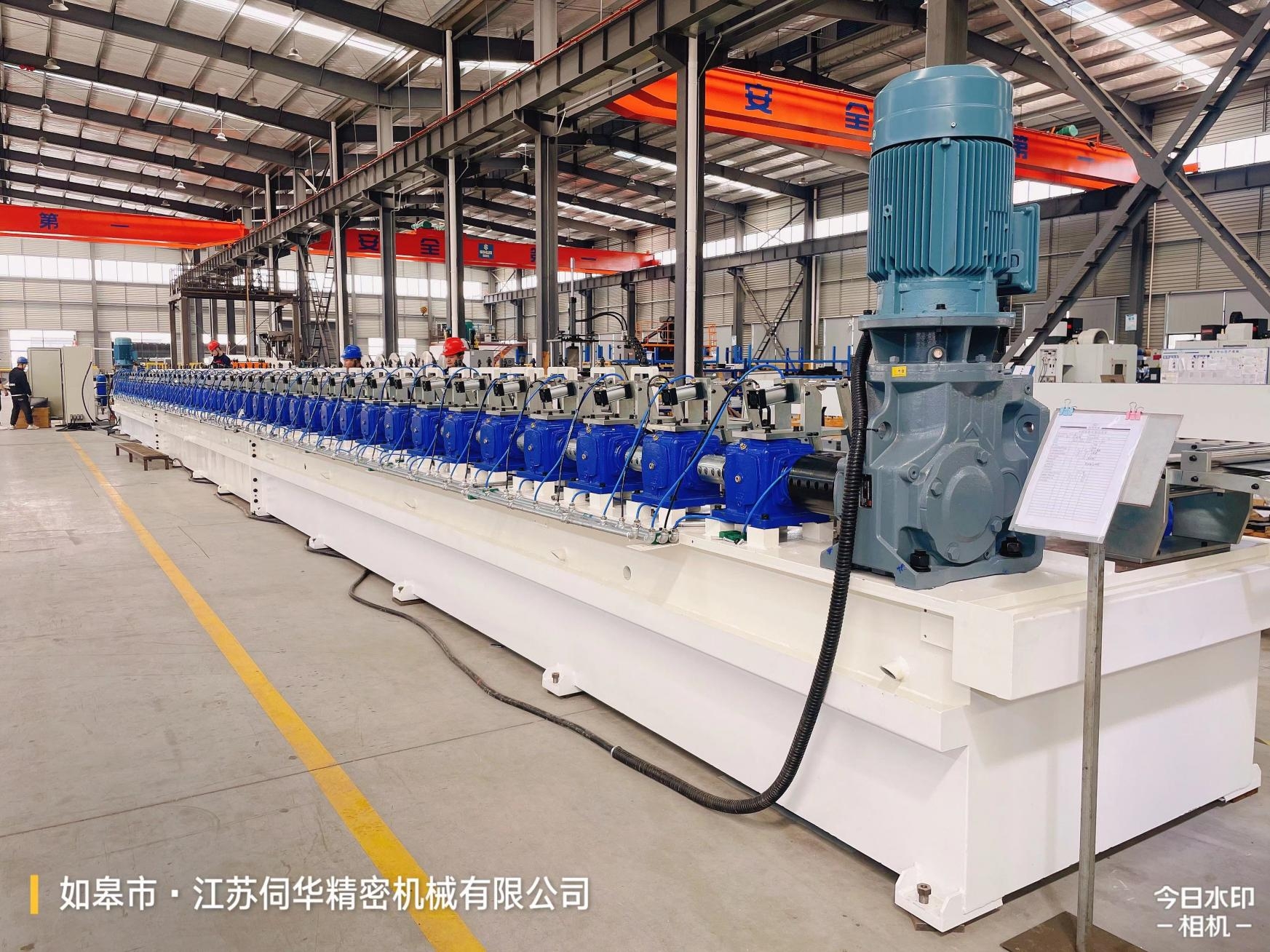

Motor power:30kw*2pc,brand:ABB. ABB Motor 2 30KW

Big Reducer :1 pc china brand

Gear box 25 pc Model T12

The machine base material is Q345-B steel by elevated temperature to eliminate inner force for prolonged machine life

The machine working board using large

CNC whole processing for high precision

flatness Working board is 25mm thickness steel

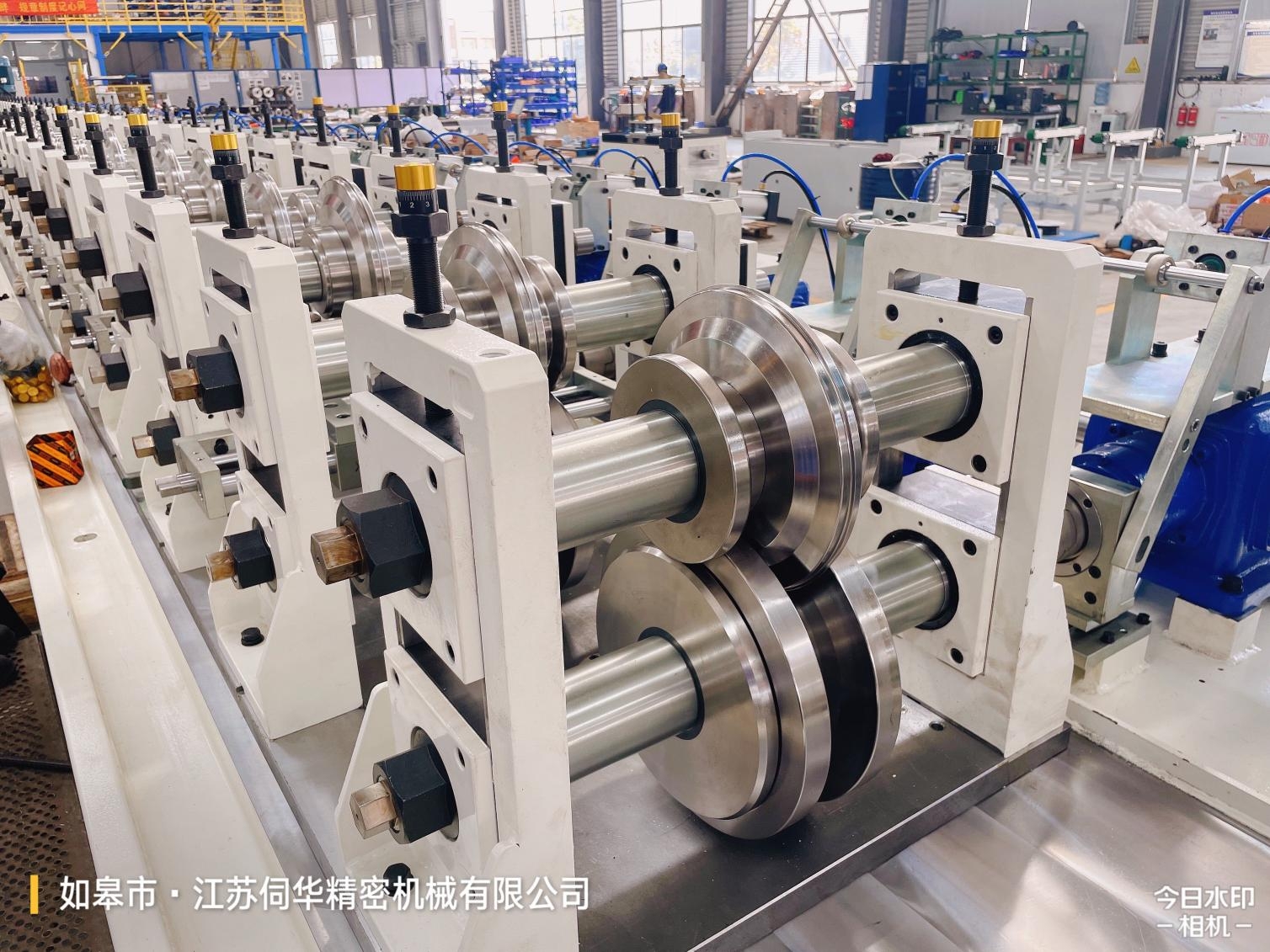

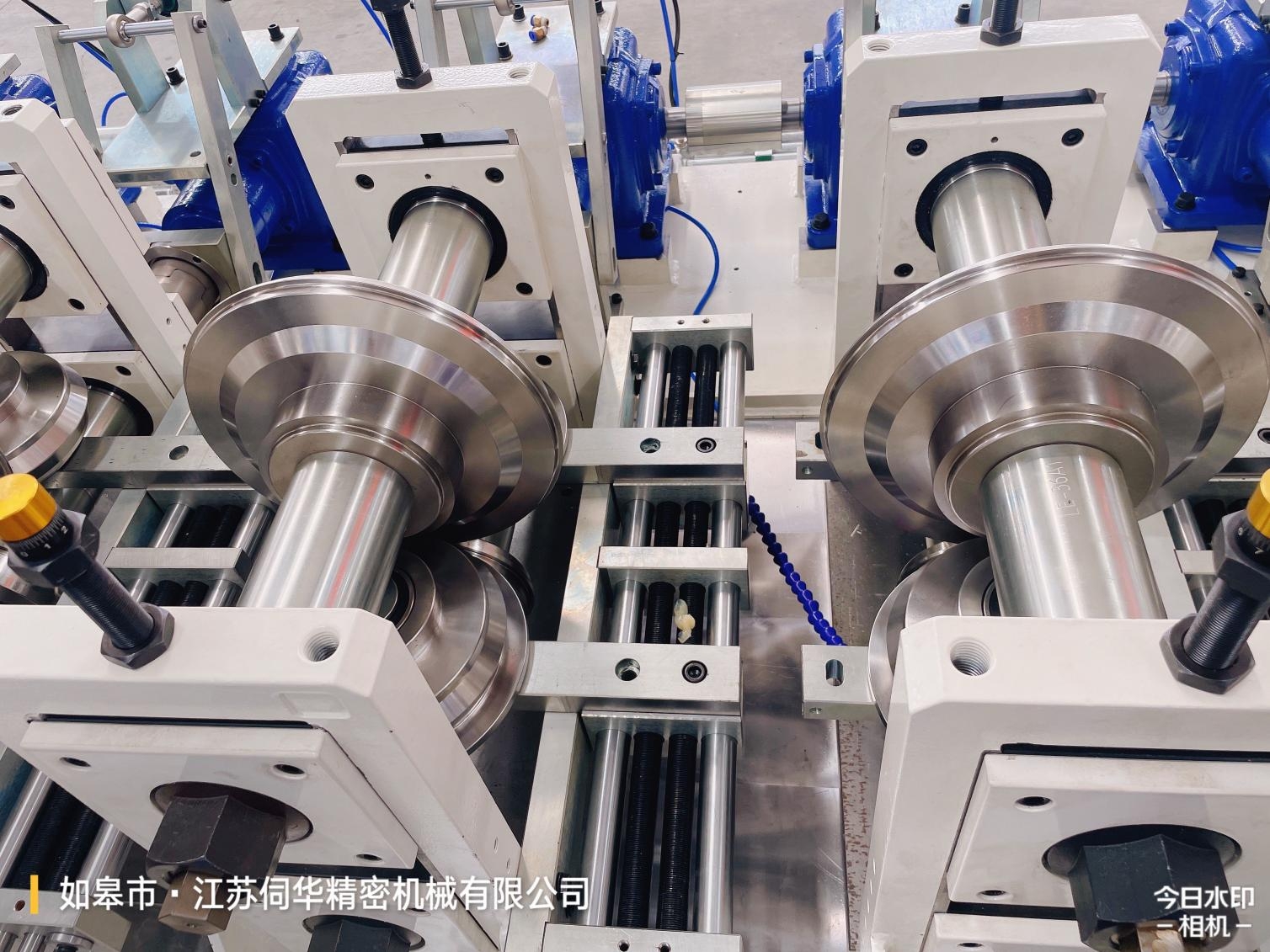

Roller row:25steps+(correct straight)

Roller material : Cr12MoV vacuum heat treatment hardness:60-62HRC

Shaft diameter:80MM,

material:40Cr , 50HRC

Bearing brand:CU/HRB CU/HRB

Wall frame material: Q345 - B, CNC

processing, distance is 0.02mm between frame and slider. Board thickness is 45mm , elevated

temperature to eliminate inner force

Slider board 45#Steel black processing

Roller row:25steps+(correct straight)

Roller material : Cr12MoV vacuum heat treatment hardness:60-62HRC

Shaft diameter:80MM,

material:40Cr ,inside 30 HRC

Bearing brand:CU

Wall frame material: Q345 - B, CNC

processing, distance is 0.02mm between frame and slider. Board thickness is 45mm , elevated

temperature to eliminate inner force

Slider board 45#Steel black processing

Roller row:15steps+(correct straight)

Roller material : Cr12MoV vacuum heat treatment hardness:60-62HRC

Guild rail:TBI (TAI WAN) TBI

Ball screw :(TAI WAN) TBI

Servo motor power:4.4kw* 1 ,brand: YASKAWA )

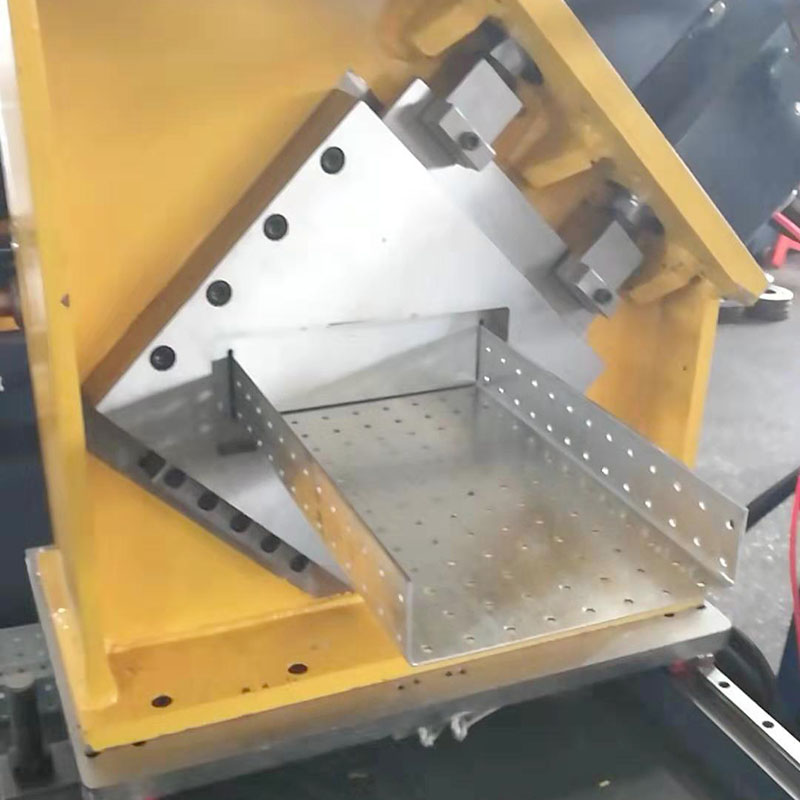

Cutting mold 10 sets, material ; SKD11 , vacuum heat treatment ,hardness 60-62HRC

Sensor Brand :Keyence

Working table with large CNC whole processing, working table is high precision

Cutting table is welded as box body structure by one type put screw and guardrail inside for safe and durable cutting table installed screwoiling device

The left and right ends of the cutting table are provided with a dust cover, a protecting gear driver and guide rail

2Cutting table base using Q235B steel gas protection welding, after 2 times the overall

tempering, eliminating the internal force

generated by welding. Using sandblasting,

spray 2 times 2 times anti rust primer, top coat, paint color is gray.

Moto11 KW ,brand:Siemens

Hydraulic pumps:TAIWAN

Accumulator model:15L

Solenoid valve number : 1PC ,

brand : SIHUA

Wind cooling

Pressure sensor: IFM(German)

Filtration brand is Parker(USA)

PLC: MITSUBISHI(Japanese brand)

Humaninterface:KINCO

Relay and breaker: Schneider (German ) Connects with machine parts by fast plug

Shear controllers (SIHUA) made in Italy

Inverter 55kwbrand: NIDEC

Packing table

Stacking table length is 12M