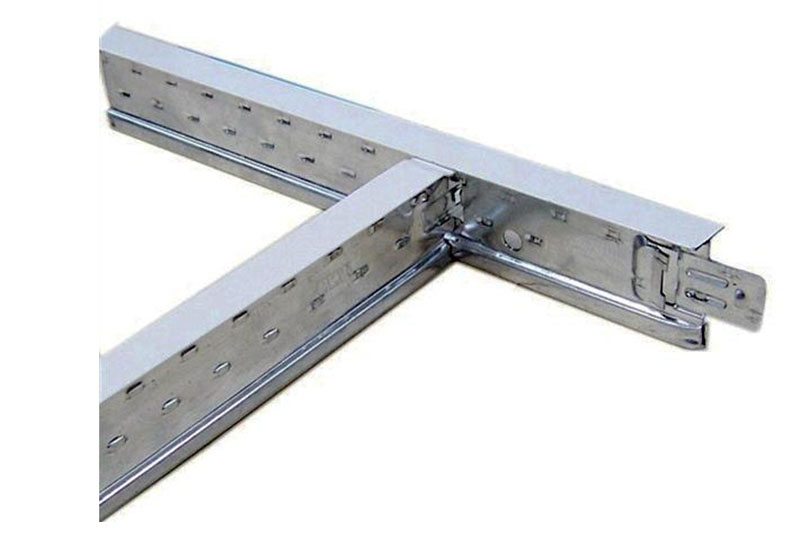

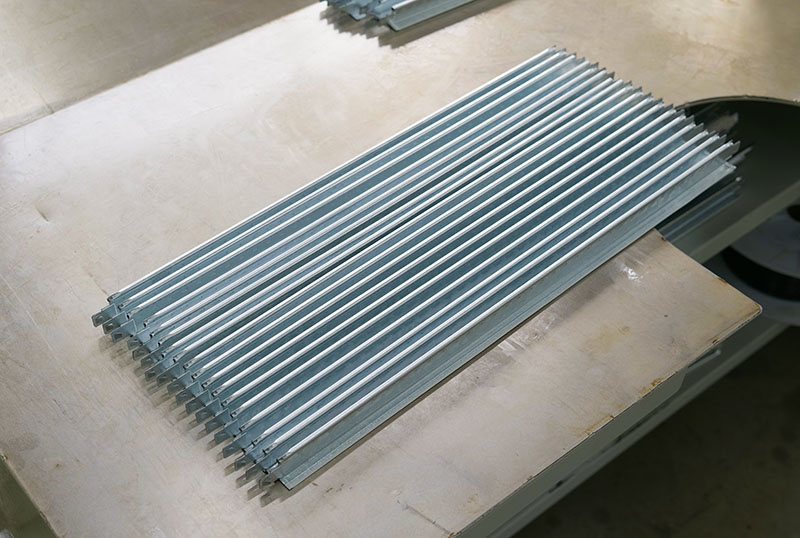

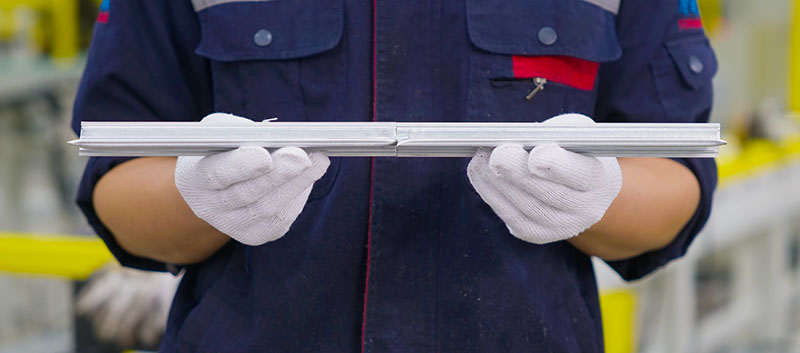

Suspened ceiling automatic long and short cross T bar steel roll forming machine

T-Bar production line can be monitored by PLC. If the T-bar production line has errors, the PLC will locate the errors. It is easy to maintenance for workers.

Cross T-Bar Production speed:

1: 4'=1 minute to produce 30PC.

2: 2'=1 minute to produce 60PC.

The machine can produce product specifications: 26*24cross-T. Different specifications exchange COMBI can be replaced in 30 minutes.

For example: 26H *24 specifications can be produced if add one set COMBI.

Electric power: 40kw.

Voltage: 380v/400v/415v 3-phase 50/60hz or as custom need.

Motor power: 15KW, Motor brands: Inovance.

Pump working pressure: 140 kg Hydraulic flow: 80L Brand is ECKERLE(Germany).

Oil cylinders, quantity: 6 pieces.

Accumulator:40L Brand: OLAER(French).

Pressure sensor, IFM (German) The magnetic valve: Rexroth 24V (German).

Filtration brand is Parker (USA).

The oil is cooled by air (as customized).

PLC brands: MITSUBISHI (JAPAN).

Frequency invertor power:15 KW brand: YASKAWA.

Relay and breaker brand: SCHNEILDER.

Human interface (touch screen) brand: KINCO, size 10.4 ".

Electric cabinet, uses the quick plug to connect outside wire.

Shear controller, brand: SI HUA (import from German).

Encode is OMRON.

Loading capacity: 3000 KGS*2.

Max coil specification: O.D. 1,500 mm. I.D.508 mm. Width: 150 mm.

By hydraulic rolling in to tighten the coil.

Loading capacity: 1500Kgs*2.

Max coil specification: O.D. 2,000 mm. I.D. 508 mm. Plate width: 100 mm.

By hydraulic rolling to tighten the coil.

Quantity of dies are 3 sets: 1pieces head cutting+1 pieces tail cutting+1 pieces Medium Hole Die.

Die material(Die cutter, Die cutting board ): DC53 Vacuum heat treatment hardness:58-62HRC.