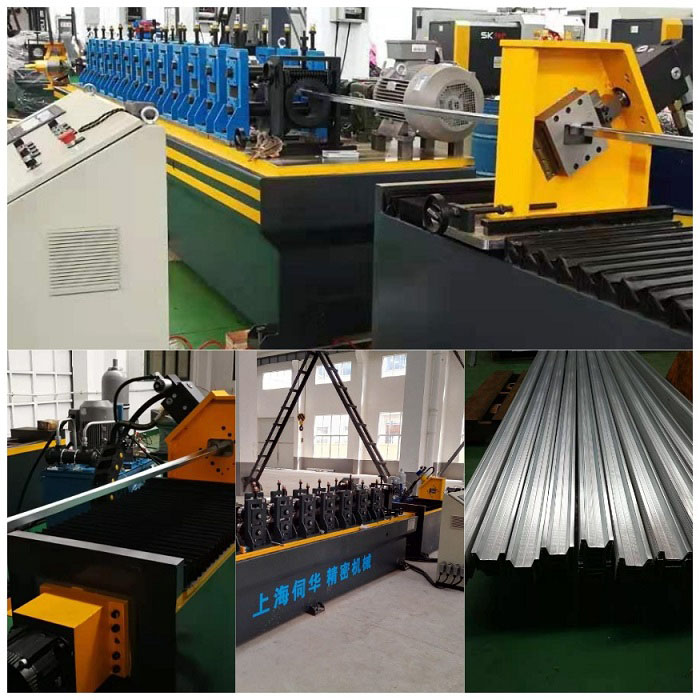

Strut C Channel Roll Forming Machine

A structural roll forming machine is a piece of equipment used in manufacturing to produce high volume, long lengths of steel structures with specific cross-sections. This includes metal channels, angles, I-beams and other profiles used in building construction, infrastructure projects and other applications. The machine works by gradually bending and forming a steel strip or coil into the desired cross-sectional shape by passing it through a series of rollers that are precisely engineered to obtain the desired profile. The end product is a continuous length of steel that can be cut to size for a variety of structural applications.

1. The products produced by this machine are widely used in support and hanger system, which can be combined with steel structure, concrete structure or other structures quickly and effectively. Quick and convenient pipe fixing, perfect air pipe and bridge support and other process installation.

2. This roll forming machine is suitable for manual replacement of different card idlers, the production of 41*21,41* 41,41 *52,41* 62,41 *72 supporting profiles. A specification profile adopts a clip roller, which saves the time of roll adjustment and debugging, and is convenient for ordinary operators to operate.