SIHUA quality hot sale customized storage rack roll forming machine

Work for material thickness:0.8-2.0mm

Main power: 18.5KW

Speed: 15-30m/min

straightening rollers: 4+5.

Shaft Material and diameter material is40CR heat treatment

Blade material: SKD11

Power: 380v/ 415V/50HZ/3 Phase(can be customized according to customer requirements)

Manual decoiler for 5T

PLC system fix with the machine

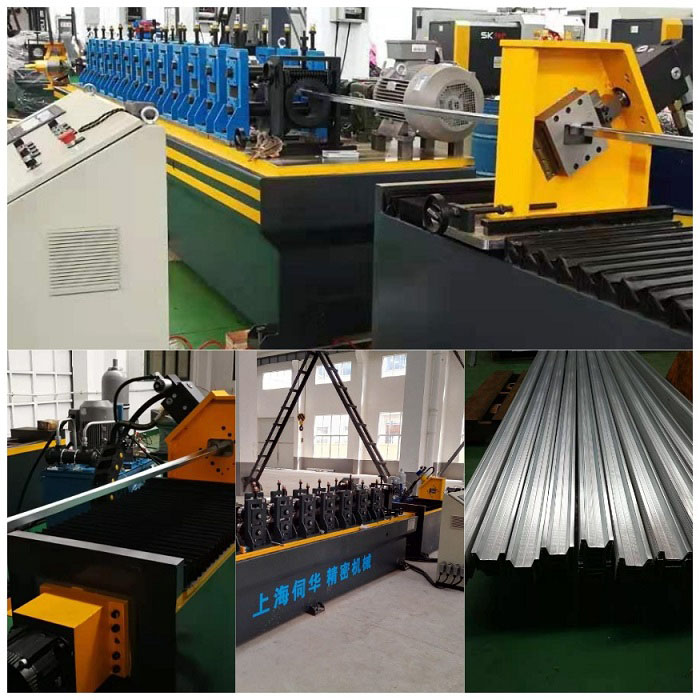

It is composed of 17 steps rollers 2 groups of supporting rollers, driving device and 2 pinch code rollers and frame.

Both sides of each rolling wheel is transmitted by needle pins all are the main force rollers. The total quantity of the rollers is 19, the diameter is φ75 and the distance between the rollers is 90mm, with supporting rollers. All the rollers material is cr12mov (mold steel ) vacuum heat treatment 58-62 degree.

The function of the supporting roller is to balance the leveling rollers force and reduce the friction to the rollers.

The working rollers can be adjusted the gap electrically which is controlled by 2 hand wheel to ensure the leveling quality.

Driving model: all the independent rollers and gear box are driven by 30Kw frequency control motor.

A storage rack roll forming machine is a type of industrial machine that is designed to produce storage racks of different sizes and shapes for use in warehouses and other storage facilities. The machine is equipped with a series of rollers through which a metal strip is fed, and it uses a series of forming rollers to create the desired shape of the storage racks. These machines are used in the production of adjustable pallet racking, drive-in and drive-through racking, cantilever racking, and other types of shelving systems used for industrial storage. The storage rack roll forming machine is efficient in producing high-quality storage racks in large quantities, making it an essential machine in the manufacturing industry.