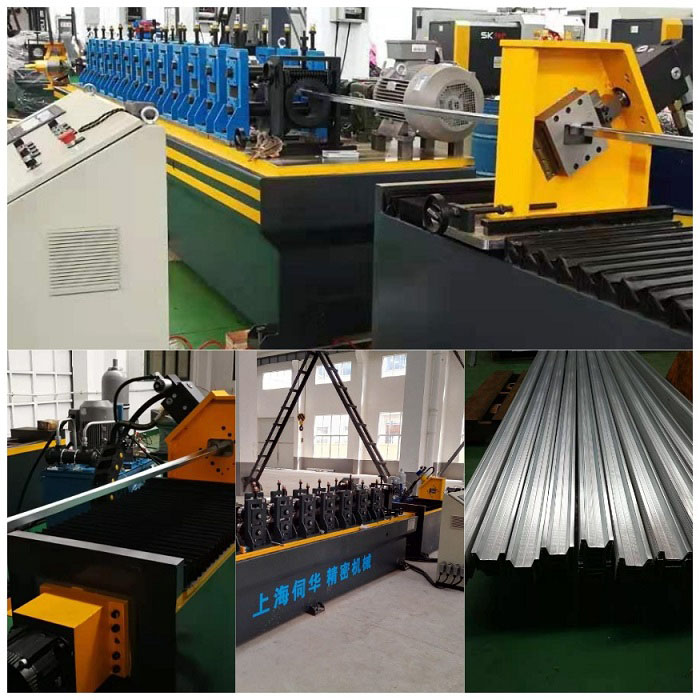

SIHUA quality hot sale cassette keel channel roll forming machine

● Automatic shear high speed high precision carrying channel forming machine.

● Machine working speed is 30-45m/min.

● Press machine punching unit prolong life.

● Profile forming machine can stable and long time working to satisfied high quantity production.

● Roller and machine base warranty is 3 years.

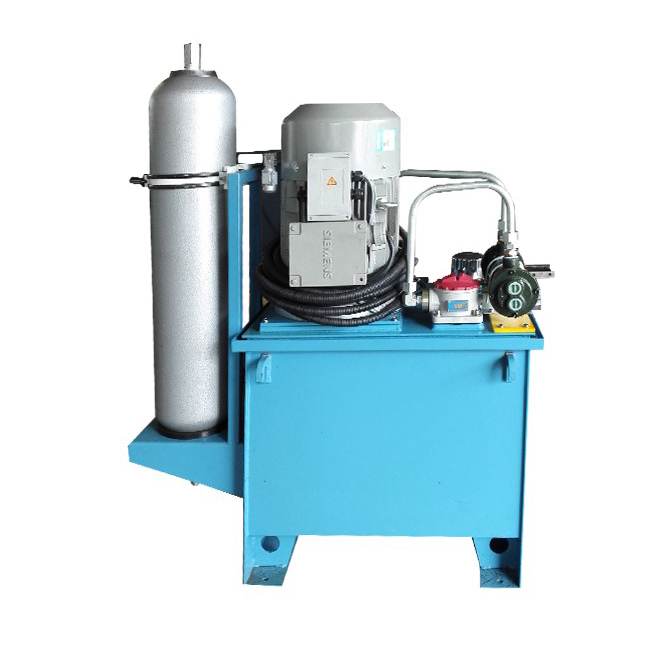

● This hydraulic cutting, so working more stable, and fast.

● Electric Control System (PLC) made in Italy.

| No. | Item | Qty | Unit |

| 1 | Single head De-coiler with straighten unit | 1 | NO |

| 2 | Introduction & Lubricating Unit | 1 | NO |

| 3 | Press machine capacity is 63 ton | 1 | NO |

| 4 | Punching die | 1 | NO |

| 5 | Roll-forming Machine Base | 1 | NO |

| 6 | Roll-forming Machine Top. 10steps rollers | 1 | NO |

| 8 | Straightener | 1 | NO |

| 9 | Cutting Unit | 1 | NO |

| 10 | Cutting die | 1 | NO |

| 11 | Hydraulic Station | 1 | NO |

| 12 | Electric Control System (PLC) | 1 | NO |

| 13 | Safety Guards | 1 | NO |

A cassette keel channel roll forming machine is a type of equipment used in the production of cassette keel channels, also known as T-grid suspended ceilings. The machine uses a roll forming process to create the metal sections that make up the cassette keel channels. Roll forming is a continuous bending process, where the metal material is fed through a series of rollers that gradually shape it into the desired profile. The cassette keel channel roll forming machine typically includes rollers, a decoiler, a straightening device, a punch station, and a cutting device. The machine can be customized to produce cassette keel channels with different shapes, sizes, and dimensions.