SIHUA quality customized hot sale omega rack roll forming machine

1. Suitable Plate Material: thickness 1.5-2.0mm, Galvanized steel or blank steel.

2. Working Speed: 12-15 meters / min.

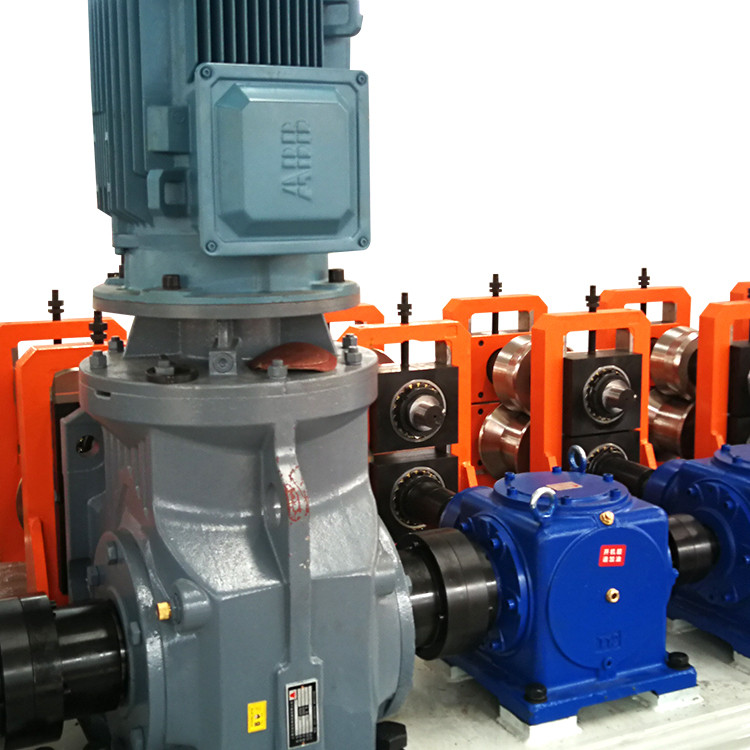

3. Forming Steps: 19 stations, drive by gear boxes.

4. Material of Roller: cr12mov vacuum heat treatment HRC58-62.

5. Material of Shaft: 45# Advanced Steel (Diameter: 75mm), thermal refining.

6. Driven system: gear box and motor.

7.Main Power with reducer: 22KW Siemens or TECO.

8. Cutting: Hydraulic Cutting with loading pin.

9. Material of Cutting Knife: vacuum heat treatment HRC58-62.

10. Hydraulic Station Power: 7.5kw.

11. The whole machine is controlled by industry computer-PLC.

12 PLC- mitsubishi(Japan).

13 Touch Screen--TECO Japan.

14 Encoder--Omron, Japan.

SIHUA QUALITY CUSTOMIZED HOT SALE OMEGA RACK ROLL FORMING MACHINE is a specific type of roll forming machine that is designed to produce omega-shaped profiles used in the construction of storage racks and shelves. The machine features advanced technology that provides accurate forming of the profile, ensuring a high-quality finished product. It can produce omega-shaped profiles of different sizes and thicknesses through adjustments of the forming rollers. The machine is customized to meet the needs and specifications of each client, ensuring that it is the perfect fit for their production requirements. The omega rack roll forming machine is an essential piece of equipment for manufacturers involved in the production of storage racks and shelves.