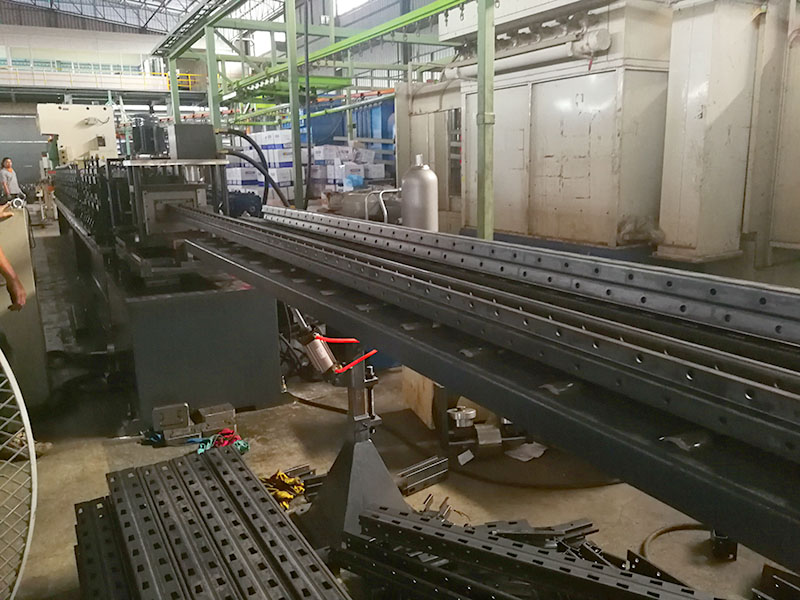

SIHUA high quality automatic customized rack roll forming machine

The production line is highly integrated by uncoiling, leveling, forming, cutting off, punching, receiving and related process. The whole production line is controlled byPCL program.

Operators can select a preset program to run the whole line automatically by using touch screen. The methods of operation include automatic control, manual control, separate operation and emergency stop.

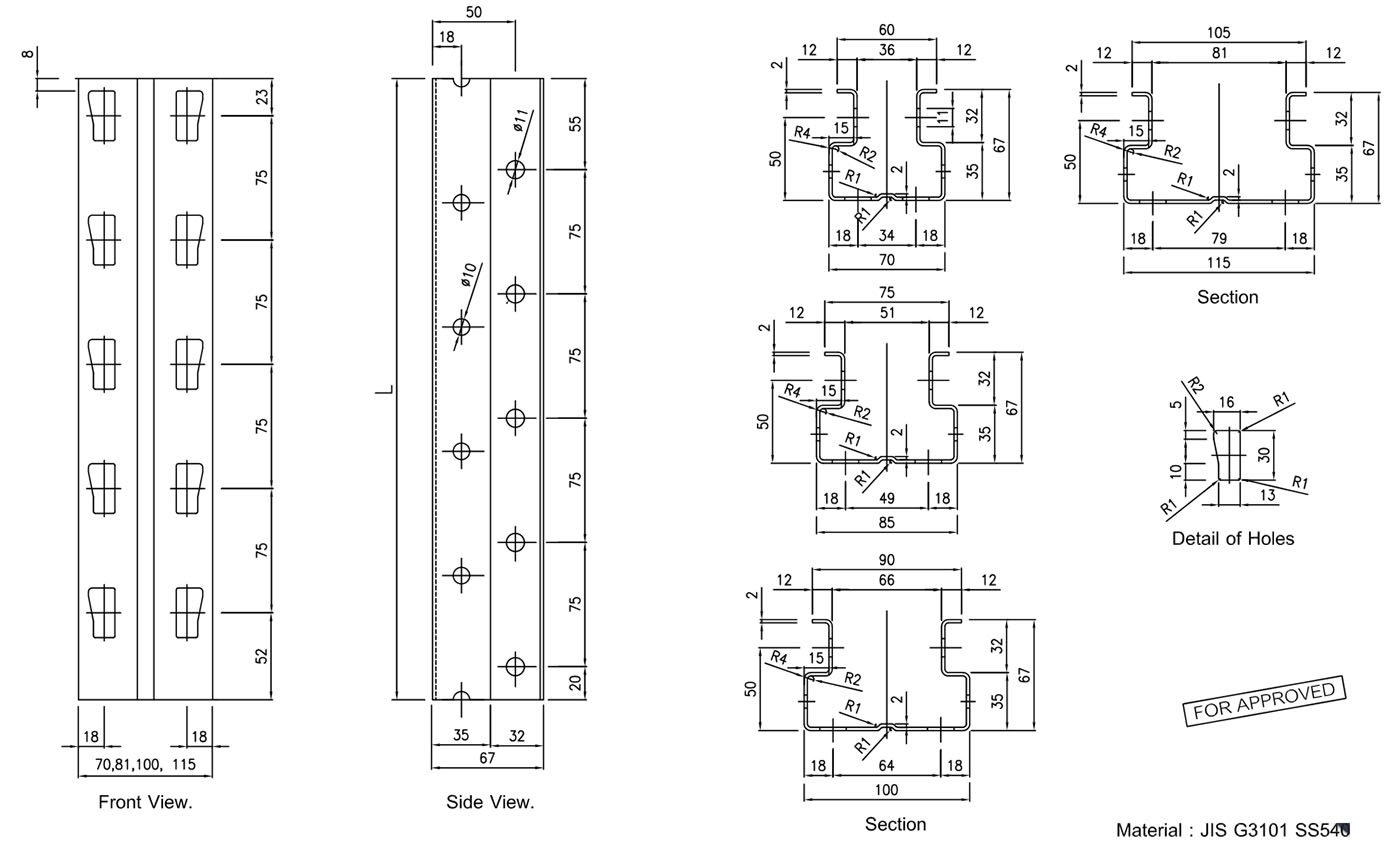

Technical Specifications of the storage shelf cold roll forming machine.

1. Good quality: We have a professional designer and experienced engineer team and the raw material and accessories we use are good.

2. Good service: we provide the technical support for whole life of our machines.

3. Guarantee period: within one year since the date of finishing commissioning. The guarantee covers all the electric, mechanic and hydraulic parts in the line except for the easy-worn parts.

4. Easy operation: All machine controlling by PLC computer controlling system.

5. Elegant appearance: Protect the machine from rust and the painted color can be customized.

6. Reasonable price: We offer the best price in our industry.

An automatic customized rack roll forming machine is a type of manufacturing equipment used to produce racks that are customized to meet specific requirements. This machine uses a roll forming process where a continuous strip of metal is fed through a series of rollers which shape and cut the metal into the desired shape for the rack. The machine is fully automated and can be programmed to produce racks of various sizes and shapes with a high degree of accuracy and consistency. It is commonly used in manufacturing facilities that produce storage and shelving systems.