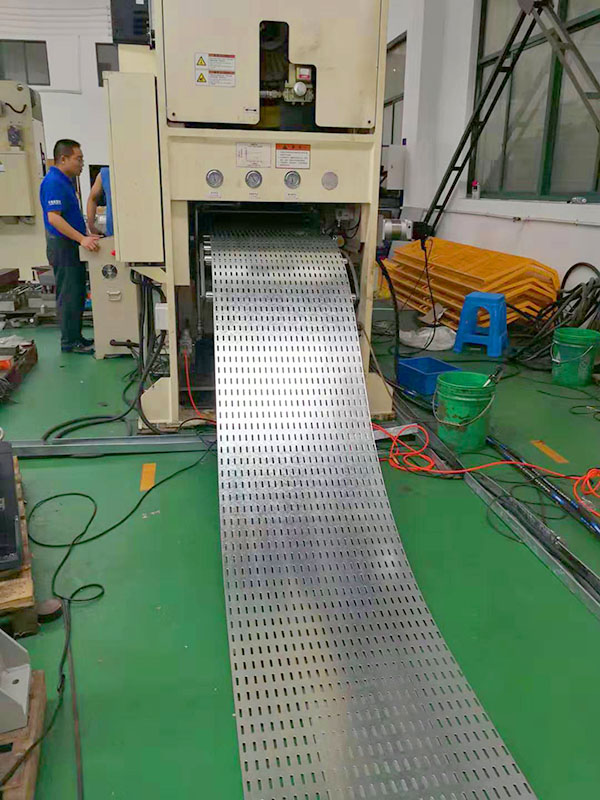

Sihua Cable Tray Roll Forming Machine

Cable tray roll forming machine (also called cable ladder roll forming machine ) is capable of making different sizes of cable trays through replacing punching molds. The cable trays produced by this roll forming machine production line are extensively used in factories and other buildings. Because of their accurate robustness. Cable tray roll forming machine consists of decoiler(uncoiler),leaving machine(leaver), servo feeding device, punching system, front cutting device, guiding device, roll former, rear straightening device and run-out table.

With full and special experience, we can customize cable tray roll forming machines or cable tray roll forming production lines according to customers"profile drawings and specifications.

| Name | Units | Quantity | |

| Decoiler | Set | 1 | |

| Main Machine | Lever, Feeder, | Set | 1 |

| forming machine | Set | 1 | |

| Cutting Equipment | Set | 1 | |

| Hydraulic system | Set | 1 | |

| Electric control system | Set | 1 | |

| Packing table | Set | 1 | |

1. Italian technology German quality roll forming machine.

2. High speed high precision roll forming machine for your excellent profile.

3. This kind of machine has the best quality and the best price. It has accurate measurement and easy operating.

4. We can design and manufacture the special type machine according to the customers' requirement and we could provide technical guiding, production, installation, debugging and maintenance service to all customers.

5. Our product has been exported to many regions and won high reputation because of the high quality and valuable price.

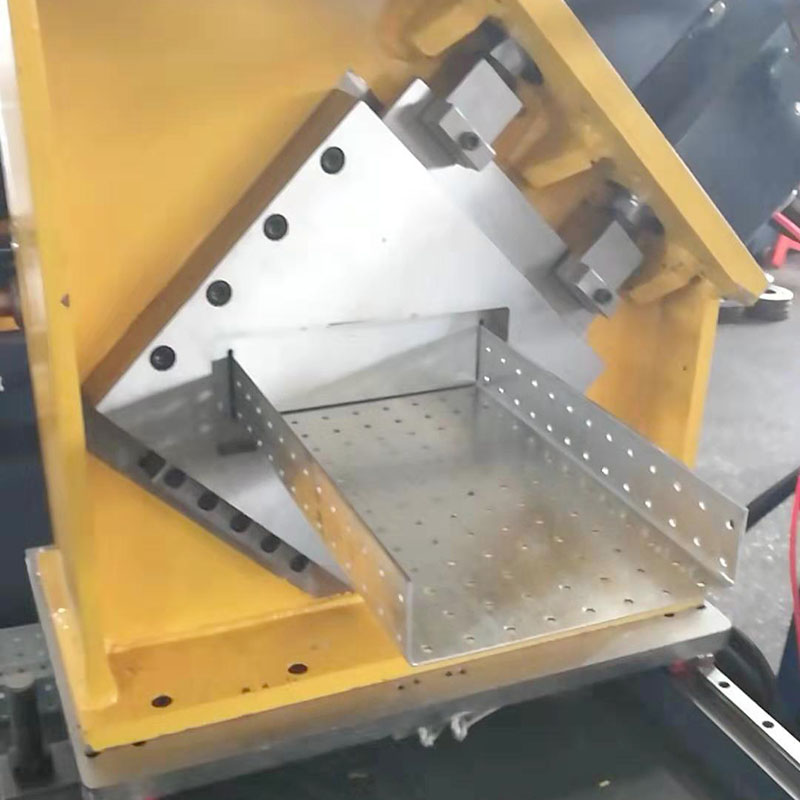

The perforated Cable Tray Roll Forming Machine is a duplex and high performance production line for manufacture C section profile with slotted holes for supporting electric wiring in commercial and industrial construction. The cable tray which was produced by Cable Tray Roll Forming Machine usually made from middle gauge steel thickness from 0.8~2.0mm.

The perforated Cable Tray Roll Forming Machine successfully integrated hydraulic punching device or high speed press machine for radiation holes on cable tray. Also, the telescope shaft is available to rapid size changeover without toll change. Pre-cut or post cut can both equipped for cut off finished product.

A whole Cable Tray Roll Forming Machine including the Decoiler, Guide device, Straighten rollers, Main Roll Forming Machine, Hydraulic system, The PLC control system and Ran-out tables. Our roll forming machine equipped with the computer control system. You just need to program in the computer the piece and length you need, then the roll forming machine produces it automatically. The machine is easy to operate, and operate stably.

| Suitable Plate Material |

|

| Material– thickness | 0.8-2.5mm |

| Raw material | Galvanized steel and black steel sheets |

| Working Speed | 15meters / min |

| Forming Steps | 8stations |

| Material of Roller | cr12mov |

| Material of Shaft | 45# Advanced Steel (Diameter: *90mm), thermal refining |

| Driven system | gear box drive, shafts diameter 70mm |

| Main Power with reducer | 22KW SIEMENS |

| Cutting | Hydraulic Cutting off |

| Material of Cutting blades | SKD11 (JAPAN) |

| Hydraulic Station Power | 11KW SIEMENS |

| The whole machine is controlled by industry computer-PLC |

|

| PLC--Mitsubishi Japan |

|

| Touch Screen—KINCO |

|

| Electric parts--Schneider |

|

| Adjust the height by the motors and the rails, controlled by the PLC |

|

Picture of cable tray machine