SIHUA automatic quality and hot sale rack upright roll forming machine

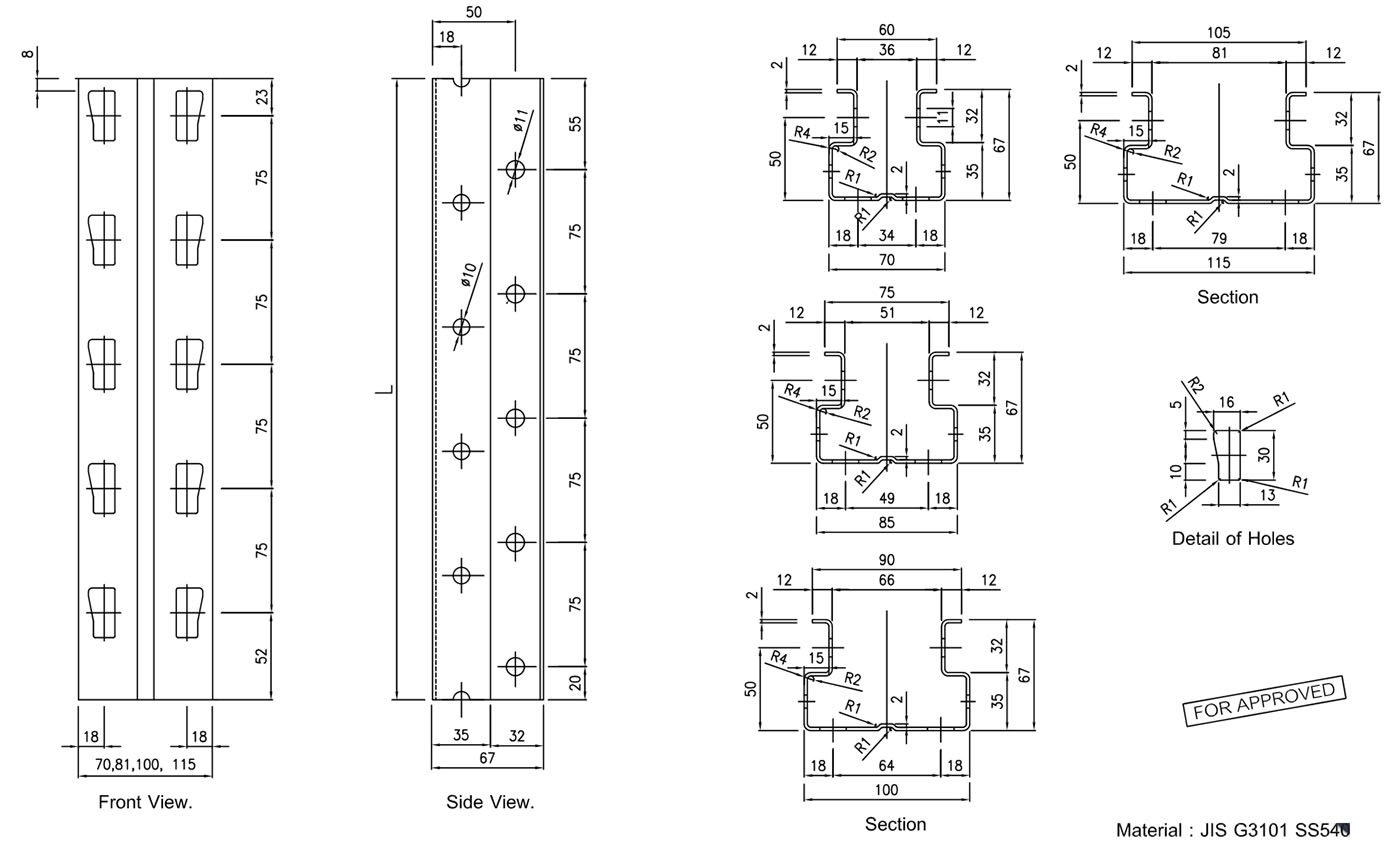

This machine takes galvanized steel or cold rolled steel as the raw materials, through the a series steps to form it into a shelving profile with specific shape and size.

The forming steps devices include decoiler, Feeding and Leveling Device, Punching device, main forming mill, hydraulic post-cutter.

The inverter controls the motor speed, the PLC system controls length and quantity automatically, therefore, the machine achieves a continuous automatic production, which is the ideal equipment for cold roll forming industry.

| Article No. | Item Name | Specification |

| 1 | Width of feeding material | As ur need profile |

| 2 | Thickness of feeding material | max 3.0 mm coil sheet |

| 3 | Roller station | 17-22stations |

| 4 | Shaft Diameter | 55-95 mm |

| 5 | Productivity | 15-25 m/min |

| 6 | Rollers' material | CR12MOV |

| 7 | Shaft material | 45# steel |

| 8 | Weight | 19 ton |

| 9 | length | 25-35m |

| 10 | Voltage | 380V 50Hz 3phases |

| 11 | Control | PLC |

| 12 | Decoiler | 8 Tons |

| 13 | Motor | 22kw |

| 14 | Driving way | Gear box |

| 15 | Electrical control system | PLC |

| 16 | Cutting system | Hydraulic cutter |

A rack upright roll forming machine is a specialized manufacturing equipment used to manufacture uprights for pallet racking systems. These machines use a series of rollers and dies to shape and form sheet metal into the desired shape and size for the rack uprights. The machine can work with various materials such as cold rolled steel, galvanized steel, or stainless steel, and it can produce uprights with varying thicknesses and dimensions to meet the specific requirements of different pallet racking systems. The resulting uprights are durable, reliable, and able to withstand heavy loads and frequent use in warehouses and logistics facilities.