Shanghai SIHUA solar pv bracket roll forming machine

A solar PV support roll forming machine is a type of equipment used in the manufacturing process of solar panel mounting structures. The machine uses a roll forming process to produce continuous lengths of metal sheets that are then cut and formed into different shapes and sizes to create various types of solar panel mounting systems.

The roll forming process involves feeding a strip of metal through a series of rollers that gradually shape the metal into the desired profile or shape. The resulting product is a continuous length of metal sheet that can be cut and formed into individual components for solar panel mounting structures.

The solar PV support roll forming machine is typically used in the renewable energy industry to produce high-quality, durable, and efficient solar panel mounting structures. These structures are designed to securely hold solar panels in place and withstand various weather conditions while maximizing their exposure to sunlight.

Overall, the solar PV support roll forming machine plays an essential role in the production of solar panel mounting structures, which are critical components of solar power systems that generate clean and sustainable energy.

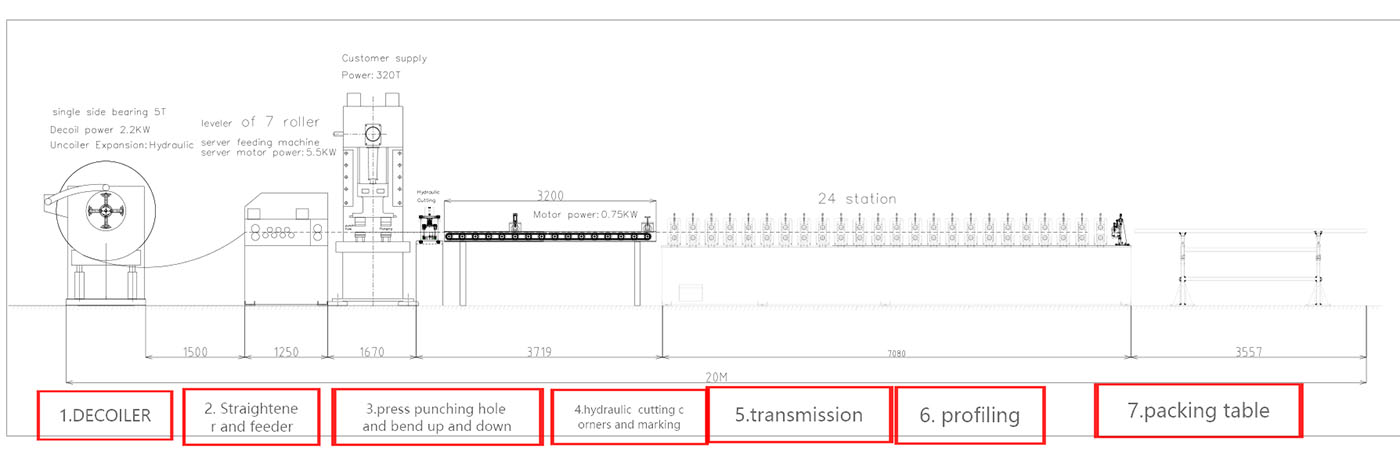

Production process: de-coiler (un-coiler, straightener, servo feeder)→press machine (punching hole)→roll forming machine →cutting machine(hydraulic system give power) all parts was control by electrical control system (details as follow)

| DECOILER, STRAIGHTENER, FEEDER | |

| Hydraulic de-coiler | Load capacity: 4 ton with loading carriage |

| Material | 2mm, S 235 JR |

| Straightener | Material width《450MM |

| Servo feeder | pitch accuracy is +-0.15mm, Brand of PLC is Mitsubishi |

| Servo motor power is 2.9 kw, brand is YASKAWA | |

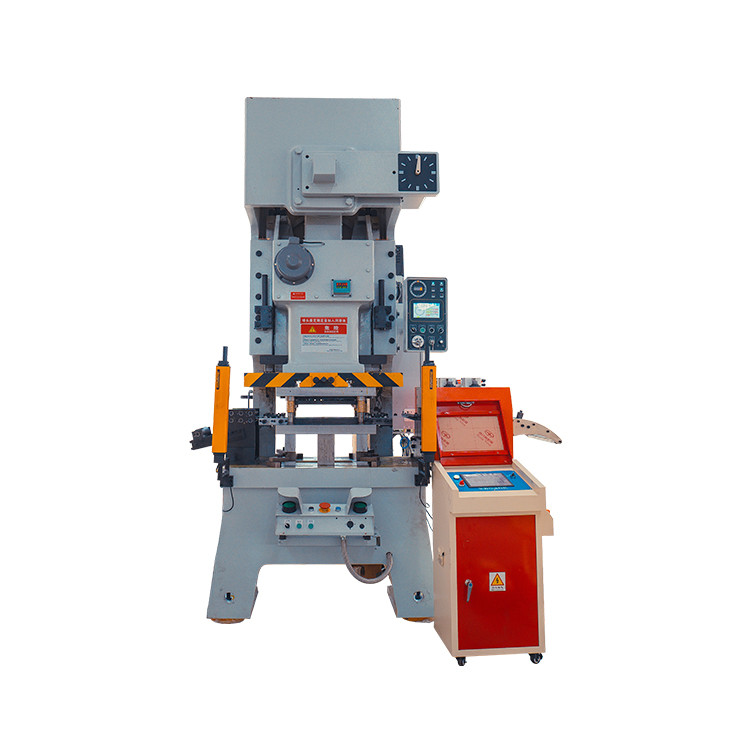

| Press machine and punching die | |

| Band YangLi Capacity is 125ton | |

| Solar pv bracket roll forming machine | |

| Product speed | 0-40m per min |

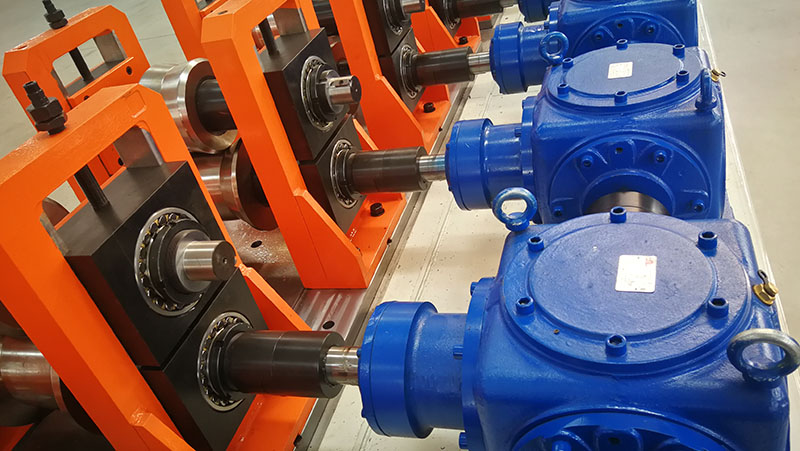

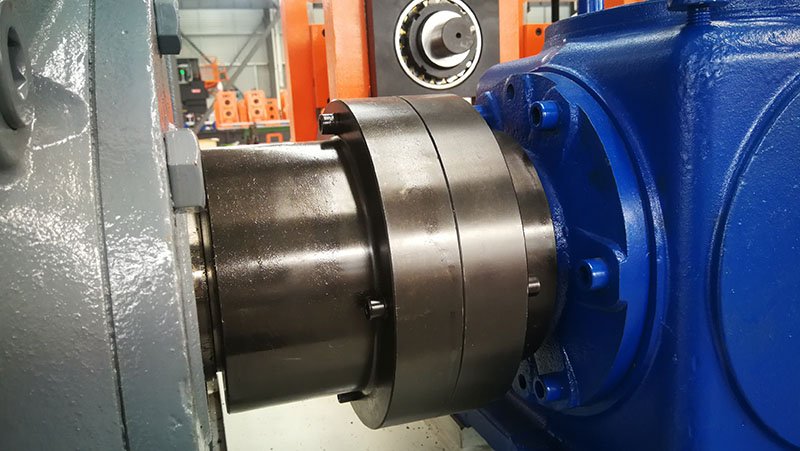

| Roller row | 20-35steps+(correct straight) |

| Shaft diameter | Φ70mm,material-40Cr,heat treatment |

| Roller material | Cr12MoV vacuum heat treatment hardness:58-62HRC |

| Motor with one big reducer Power | 45KW Brand siemens |

| Bevel gear reducer model | T10 |

| Installed cooling for each roller | |

| Cutting table with locate pin | |

| Cut mold | 4 sets |

| Material | SKD11 |

| Guide rail brand | TBI |

| Cylinder | ARITAC |

| Servo motor brand Yaskawa 4.4kw | |

| Hydraulic system | |

| Hydraulic pump flow | 50L/min |

| Motor power | 11KW; SIEMENS |

| Hydraulic solenoid value number | 2set, REXROTH |

| Hydraulic accumulator capacity 25L | |

| Tank volume | 220L |

| Electric control system | |

| Encoder | OMRON(Japanese brand) |

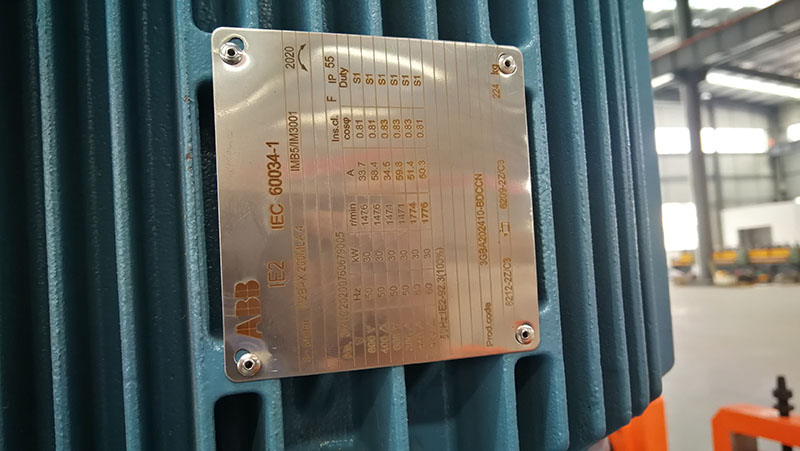

| Frequency motor | 45KW (NIDEC) |

| PLC | MITSUBISHI(Japanese brand) |

| Human interface | KINCO |

| Relay | OMRON(Japanese brand) |

| Packing table | |

| Length | 6.5 M |