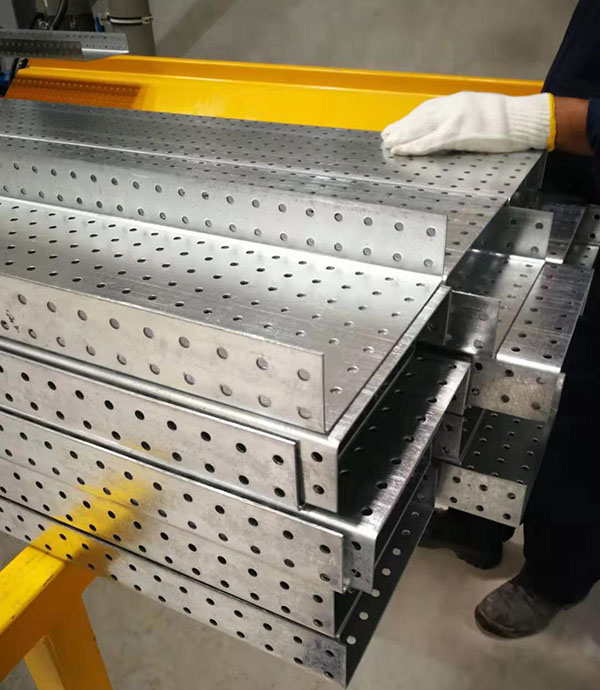

Shanghai SIHUA quality and customized steel channel lintel roll forming machine

Steel channel lintel is a structural horizontal block that spans the space or opening between two vertical supports. It can be a decorative architectural element, or a combined ornamented structural item. It is often found over portals, doors, windows and fireplaces. All lintels are produced by Galvanized steel or Stainless steel, it make the construction system more and more strong.

The lintel channel which was produced by lintel Roll Forming Machine usually made from middle gauge steel thickness from 1.5~2.0mm.

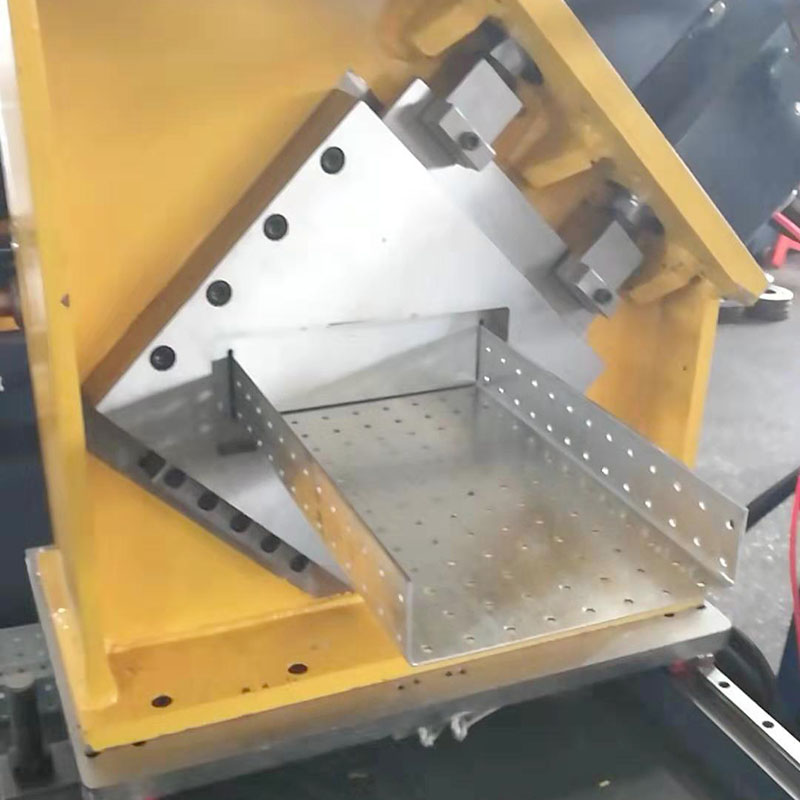

The perforated lintel Roll Forming Machine successfully integrated hydraulic punching device or high speed press machine for radiation holes on lintel profile. Also, the telescope shaft is available to rapid size changeover without toll change. position cut to cut off finished product between two holes.

A whole Lintel Roll Forming Machine including the Decoiler, Guide device, Straighten rollers, Feeder, Press machine, Main Roll Forming Machine, Hydraulic system. The PLC control system and Ran-out tables.

Our roll forming machine equipped with the computer control system. You just need to program in the computer the piece and length you need, then the roll forming machine produces it automatically. The machine is easy to operate, and operate stably.

Introduction

Production process: decoiler→straightener→ servo feeder→press machine→roll forming machine→cutting table→stacking table (hydraulic system give power) all parts were control by electrical control system

| No. | Items | Quantity |

| 1.1 | Separate UN-coiler | 1set |

| 1.2 | COMBI contain Servo straightener and feeder TNCF5-400 | 1set |

| 1set | ||

| 2 |

Punching mold: |

1set |

| 3 | Profile roll forming machine | 1 set |

| 4 |

Cutting table |

1set |

| 5 | Hydraulic system | 1set |

| 6 | Electric control system | 1set |

| 7 | Packing table | 1 piece |

| 8 | Press machine | 1 SET |