Scaffolding walkboard roll forming machine

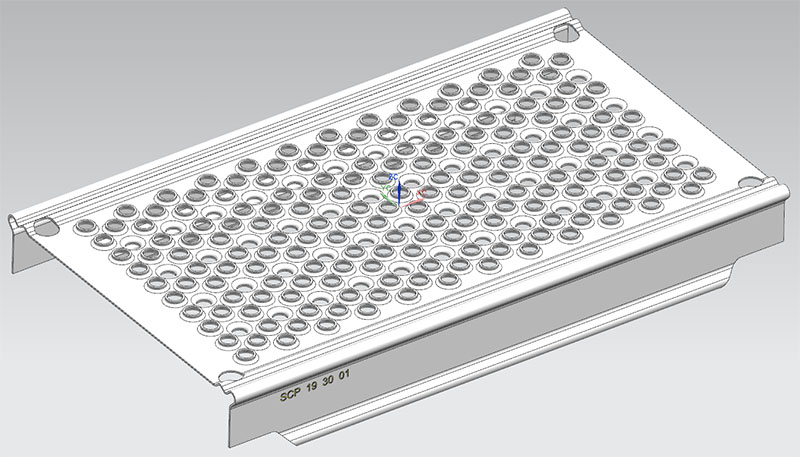

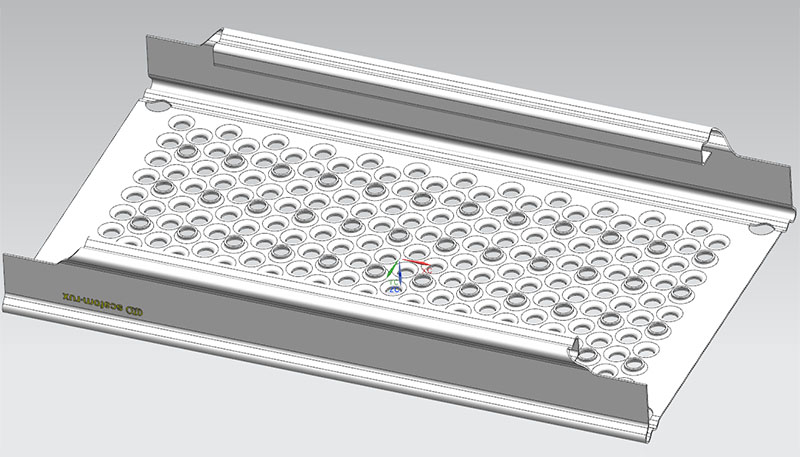

Scaffold panel roll forming machines are the ultimate solution to meet the needs of modern scaffold panel production. With its cutting-edge technology and advanced features, the machine offers unrivaled speed, accuracy and efficiency in producing high-quality scaffolding panels. Its automatic feeding system and adjustable roller settings make it easy to customize scaffolding panels of different sizes and thicknesses, while its precision cutting system ensures clean and accurate cuts every time. With its ergonomic design and low maintenance requirements, the Scaffold Deck Roll Forming Machine is a solid investment for manufacturers looking to optimize their production processes and stay ahead of the competition.

Scaffold board forming machine is an indispensable equipment in the scaffolding industry. It is designed to produce high quality steel decks that meet the demanding requirements of scaffolding systems. With its efficient and precise roll forming process, the machine ensures consistent quality and maximizes productivity. Its advanced control system provides accurate and reliable control over the entire production process, making it easy to use and highly reliable. The steel table top produced by the scaffold table forming machine is durable and has excellent load-bearing capacity, which provides a safe working platform for workers on the scaffold. The machine can handle sheet thicknesses from 1.0mm to 2.5mm, making it versatile and suitable for a wide range of scaffolding applications. It is easy to adjust and can produce steel decks of various sizes to meet different scaffolding requirements. In conclusion, a scaffolding panel roll forming machine is an important investment for any scaffolding manufacturer or contractor, capable of quickly and efficiently producing high quality steel panels for scaffolding systems of all types and sizes.