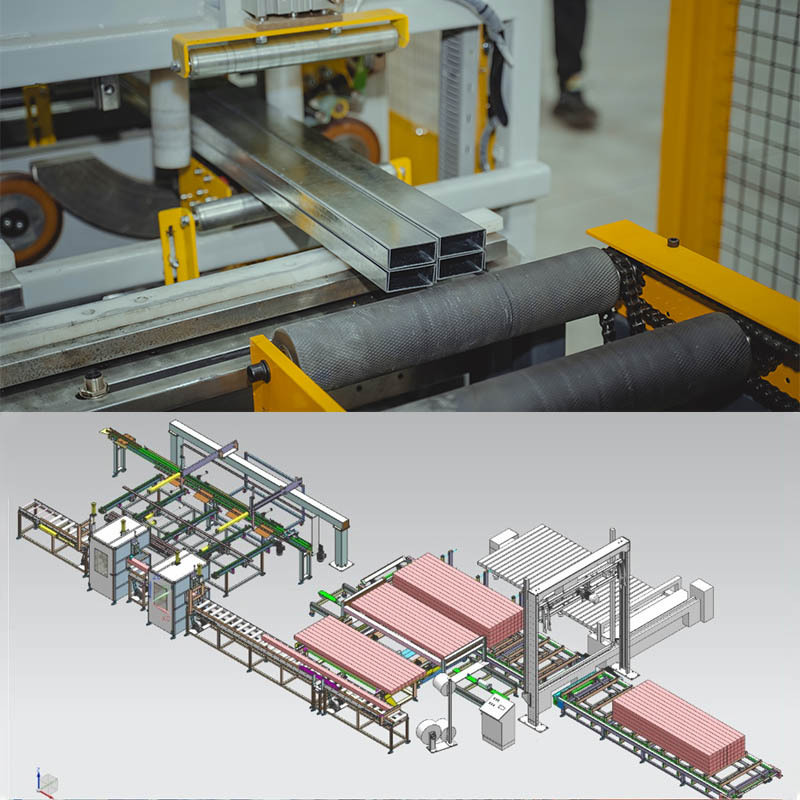

Quality packing roll forming machine

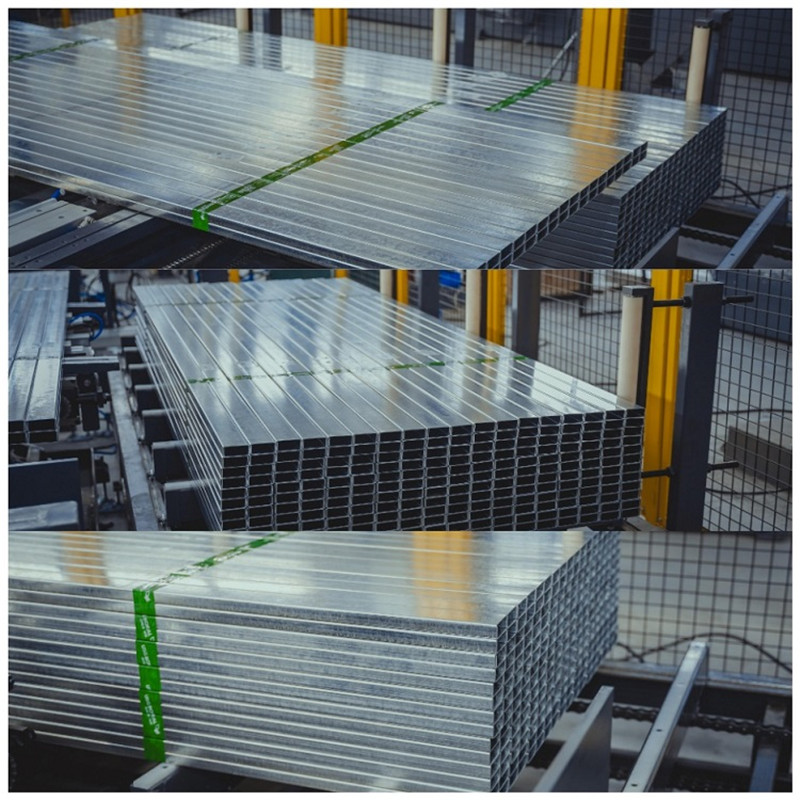

In the production and packaging process of various products, packing system machines are utilized to automate and streamline the packaging process. These machines play a significant role in ensuring that goods are efficiently and effectively packaged for storage or shipment. There are different types of packing system machines, including filling machines, sealing machines, labeling machines, wrapping machines, palletizing machines, and cartoning machines. Filling machines are used to fill containers with liquid or granular products, while sealing machines use heat or adhesive to seal packaging materials such as bags, pouches, or cartons. Labeling machines apply labels onto products or packaging materials, whereas wrapping machines wrap products with protective materials like plastic film, paper, or foil. Palletizing machines stack and arrange products onto pallets for more efficient storage and transportation, while cartoning machines assemble and pack products into cartons for storage or shipping purposes. In summary, packing system machines are essential equipment in the manufacturing and packaging process of different products, playing a vital role in improving efficiency and reducing waste in the supply chain process.

A packing system machine is a mechanical device that automates the process of packaging and filling various types of products. The machine can handle different kinds of materials such as powders, granules, liquids, and solids. It is equipped with a conveyor system that moves the product to be packaged towards the filling station where it is dispensed into the packaging material. The machine also has a sealing station where the package is sealed and labeled. With its high-speed operation, the machine significantly increases efficiency and reduces labor costs compared to manual packaging methods. Packing system machines are commonly used in industries such as food processing, pharmaceuticals, and consumer goods manufacturing, where consistent and accurate packaging of products is crucial.