Welcome to our websites!

News

-

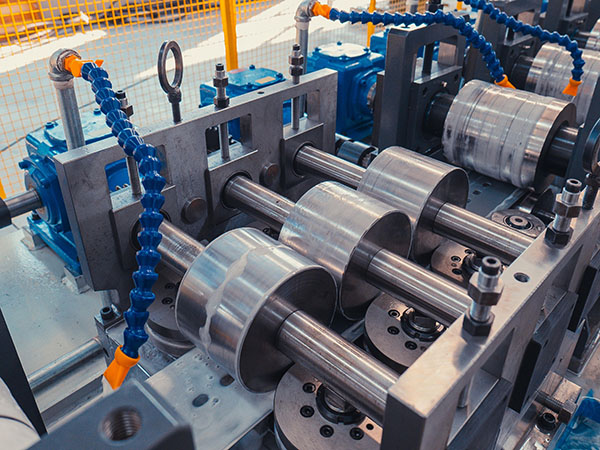

What is roll forming?

Roll forming is a flexible, responsive and cost-effective alternative to extrusion, press braking, and stamping. Roll forming is a continuous metal forming process used to shape and bend metal coils into various complex shapes and profiles with uniform cross-sections. The process uses sets of rol...Read more -

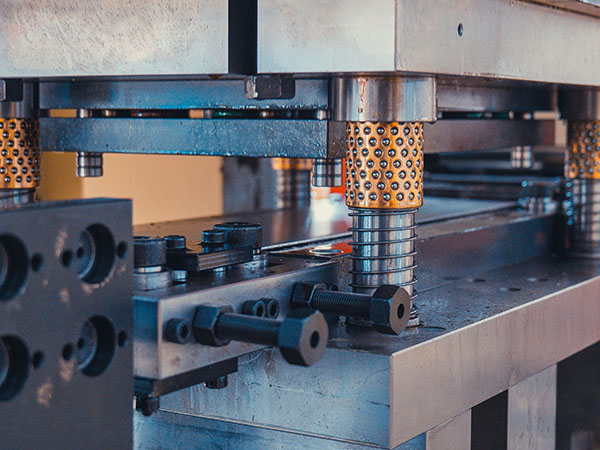

How roll forming machines work?

A roll forming machine bends metal at room temperature using a number of stations where fixed rollers both guide the metal and make the necessary bends. As the strip of metal travels through the roll forming machine, each set of rollers bend the metal a little more than the previous station of ro...Read more -

Sustainability and cash flow of efficient processes

Solving the problem of process efficiency has two positive effects. First of all, introducing coil-fed processing into the process – as we've seen – produces raw material savings that can even be in excess of twenty percent for the same quantity of product and that mean...Read more