Manufacturer of Shelves Rack Roll Forming Production Line with High Quality

Our progress depends within the advanced products, fantastic talents and repeatedly strengthened technology forces for Manufacturer of Shelves Rack Roll Forming Production Line with High Quality, Welcome to post your sample and color ring to allow us to produce according in your specification.Welcome your inquiry! Seeking ahead to building long-term cooperation along with you!

Our progress depends within the advanced products, fantastic talents and repeatedly strengthened technology forces for China Rack Shelf Forming Machine and Shelf Rack Roll Forming Machine, because of our company has been persisting in the management idea of “Survival by Quality, Development by Service, Benefit by Reputation” . We fully realize the good credit standing, the high quality goods, the reasonable price and the skilled services are the reason that the customers choose us to be their long-term business partner.

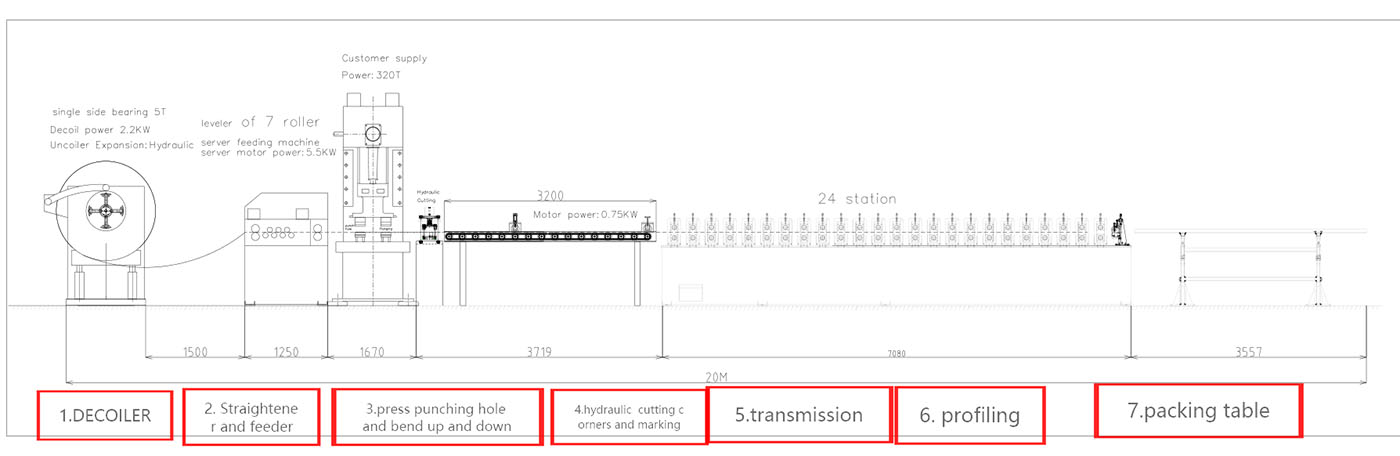

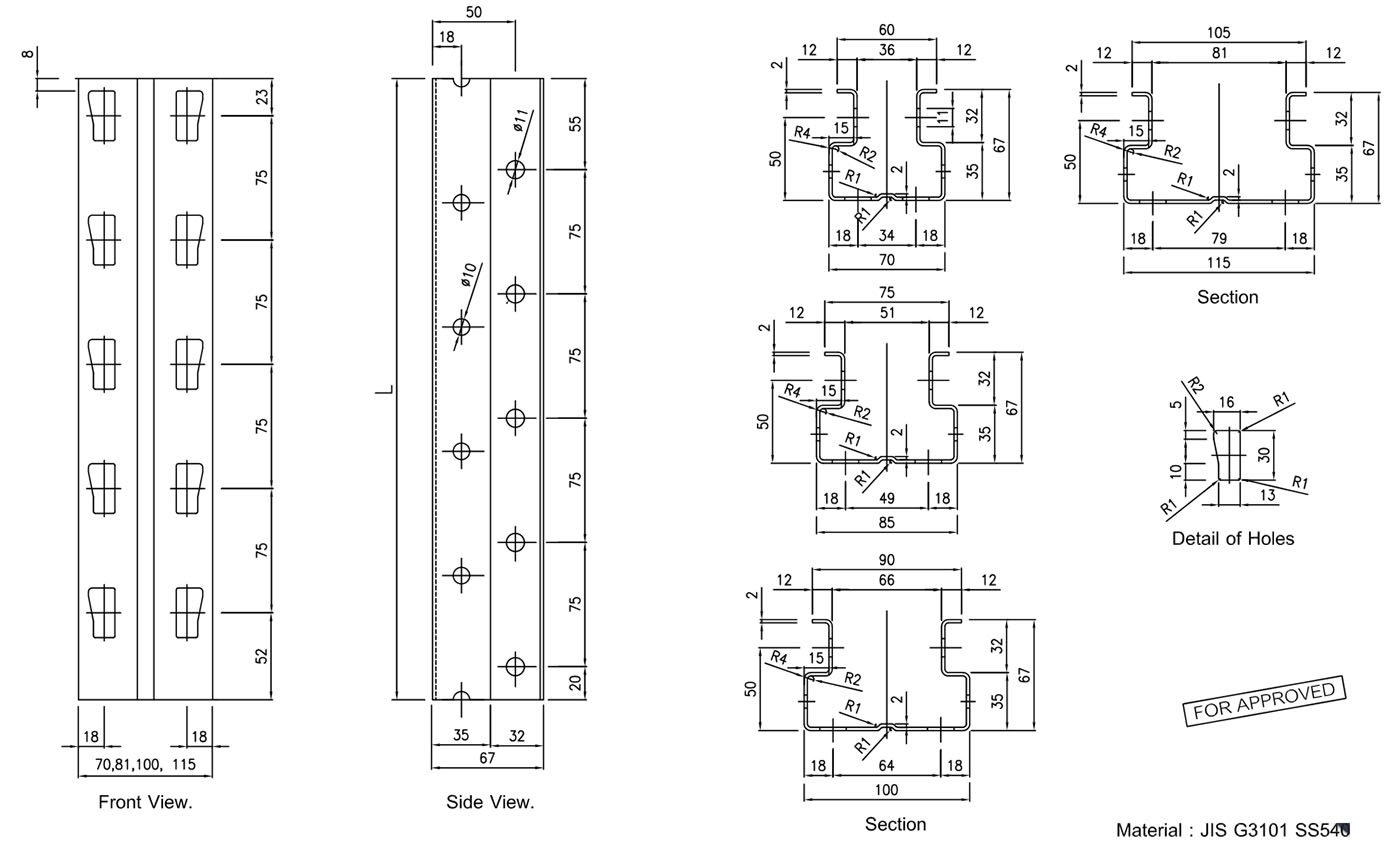

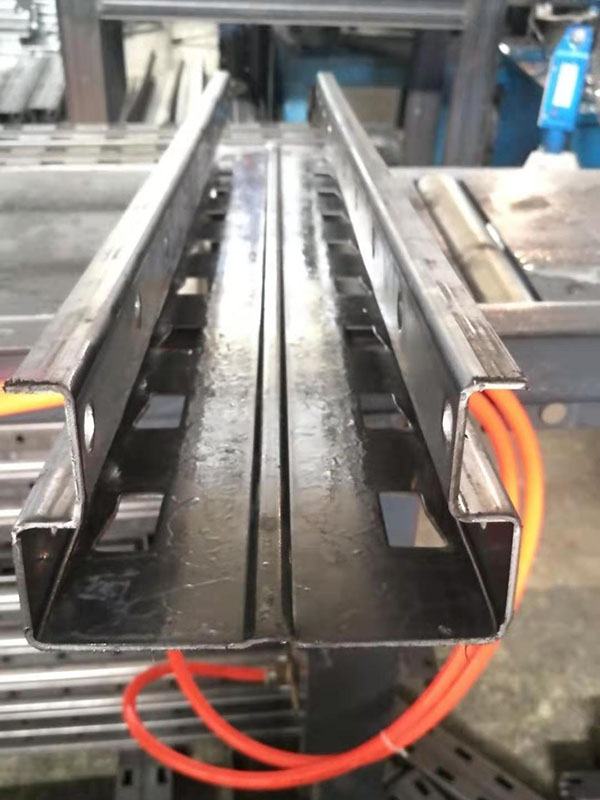

This machine takes galvanized steel or cold rolled steel as the raw materials, through the a series steps to form it into a shelving profile with specific shape and size.

The forming steps devices include decoiler, Feeding and Leveling Device, Punching device, main forming mill, hydraulic post-cutter.

The inverter controls the motor speed, the PLC system controls length and quantity automatically, therefore, the machine achieves a continuous automatic production, which is the ideal equipment for cold roll forming industry.

Production process: de-coiler (un-coiler, straightener, servo feeder)→press machine (punching hole)→roll forming machine →cutting machine(hydraulic system give power) all parts was control by electrical control system (details as follow)

| 3 IN1 COMBE | |

| Hydraulic de-coiler | Load capacity:4 ton with loading carriage |

| Material | 2mm, S 235 JR |

| Straightener | Material width《450MM |

| Servo feederfeed | pitch accuracy is +-0.15mm, Brand of PLC is Mitsubishi |

| Servo motor power is 2.9 kw, brand is YASKAWA | |

| Press machine and punching die | |

| Capacity is 125ton | |

| Storage rack upright roll forming machine | |

| Product speed | 20-30m per min |

| Roller row | 22steps+ (correct straight) |

| Shaft diameter | Φ70mm, material-40Cr, heat treatment |

| Roller material | Cr12MoV vacuum heat treatment hardness: 58-62HRC |

| Motor with one big reducer Power | 30KW Brand siemens |

| Bevel gear reducer model | T10 22pc |

| Installed cooling for each roller | |

| Cutting table with locate pin | |

| Cut mold | 4 sets. Material:SKD11 |

| Guide rail brand | HIWIN |

| Cylinder | ARITAC |

| Servo motor brand Yaskawa 4.4kw | |

| Hydraulic system | |

| Hydraulic pump flow | 50L/min |

| Motor power | 11KW; SIEMENS |

| Hydraulic solenoid value number | 2set, REXROTH |

| Hydraulic accumulator capacity 25L | |

| Tank volume | 220L. |

| Electric control system | |

| Encoder | OMRON(Japanese brand) |

| Frequency motor | 30KW (TECO) |

| PLC | MITSUBISHI (Japanese brand) |

| Human interface | KINCO |

| Relay | OMRON (Japanese brand) |

| Packing table | |

| Length | 6.5 M |

Our progress depends within the advanced products, fantastic talents and repeatedly strengthened technology forces for Manufacturer of Shelves Rack Roll Forming Production Line with High Quality, Welcome to post your sample and color ring to allow us to produce according in your specification.Welcome your inquiry! Seeking ahead to building long-term cooperation along with you!

Manufacturer of China Rack Shelf Forming Machine and Shelf Rack Roll Forming Machine, because of our company has been persisting in the management idea of “Survival by Quality, Development by Service, Benefit by Reputation” . We fully realize the good credit standing, the high quality goods, the reasonable price and the skilled services are the reason that the customers choose us to be their long-term business partner.