Italian technology ceiling cross t bar machine cross t bar roll forming machine

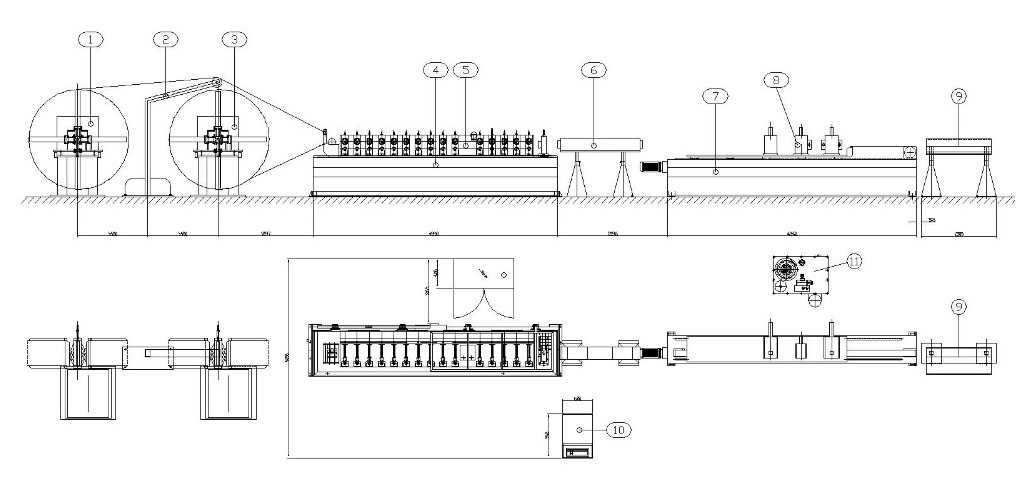

Machine Introduction (Cross t bar length 600/1200mm)

1. T-Bar production line can be monitored by PLC. If the T-bar production line has errors, the PLC will locate the errors. It is easy to maintenance for workers.

2. The speed of T-Bar Production is in 0-80M/min. Average speed is 36m per min. One minute can produce 10PCS length 3660mm (12FT) main-Tree.

3. Different specifications Roller forming units(6) can be replaced in 30 minutes, 24X32H specifications can be produced if add one set roller forming units(6).

Process Working Flow

|

NO. |

Part Names | Quantity |

| 1 |

Double de-coiler (paint steel coil) |

1 |

| 2 |

Storage unit for paint steel. |

1 |

| 3 |

Double de-coiler (galvanized steel coil) |

1 |

| 4 |

Roll former base. |

1 |

| 5 |

T-bar roller forming working units. With reducer interchange roller |

1 |

| 6 |

Cutting table base |

1 |

| 7 |

Punching dies. |

1 |

| 8 |

Packaging platform |

1 |

| 9 | Control panel (Electric control system) | 1 |

| 10 |

Hydraulic installations |

1 |

A Ceiling Cross T Bar Machine or Cross T Bar Roll Forming Machine is a specialized equipment used in the manufacturing industry for producing T-shaped ceiling grids or T-bars that are used to support ceiling tiles. This machine uses Italian technology and is fully automated and computer-controlled, ensuring high precision and speed in the production process. The machine works by feeding flat metal sheets that are then passed through a series of rollers and formed into the required T-bar shape. The final product is cut to the desired length and can be used directly in construction projects without the need for further processing. This type of machine is commonly used in the construction industry for producing ceiling grids used in suspended ceiling systems.