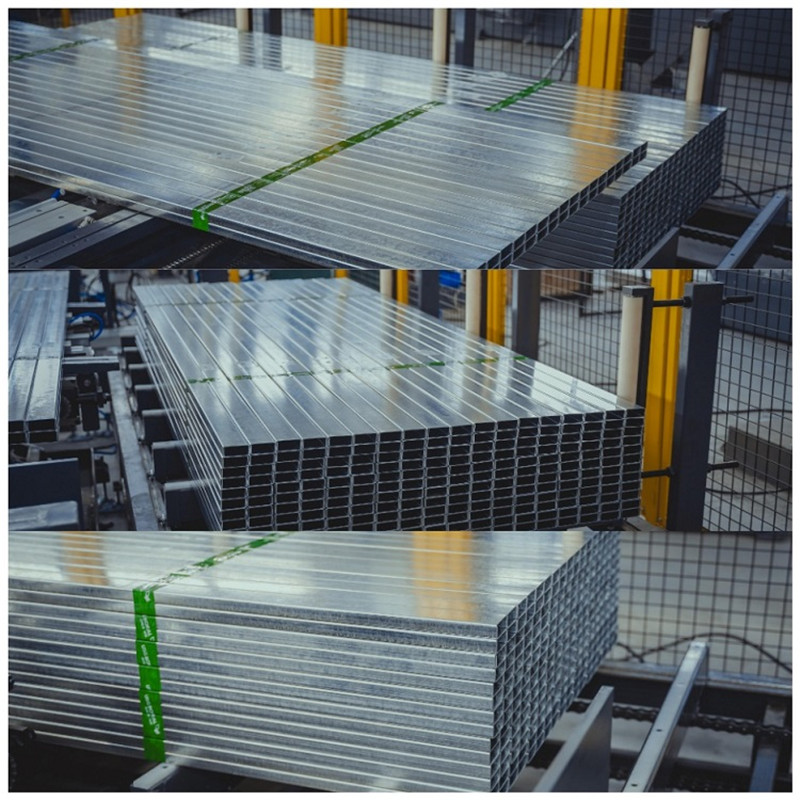

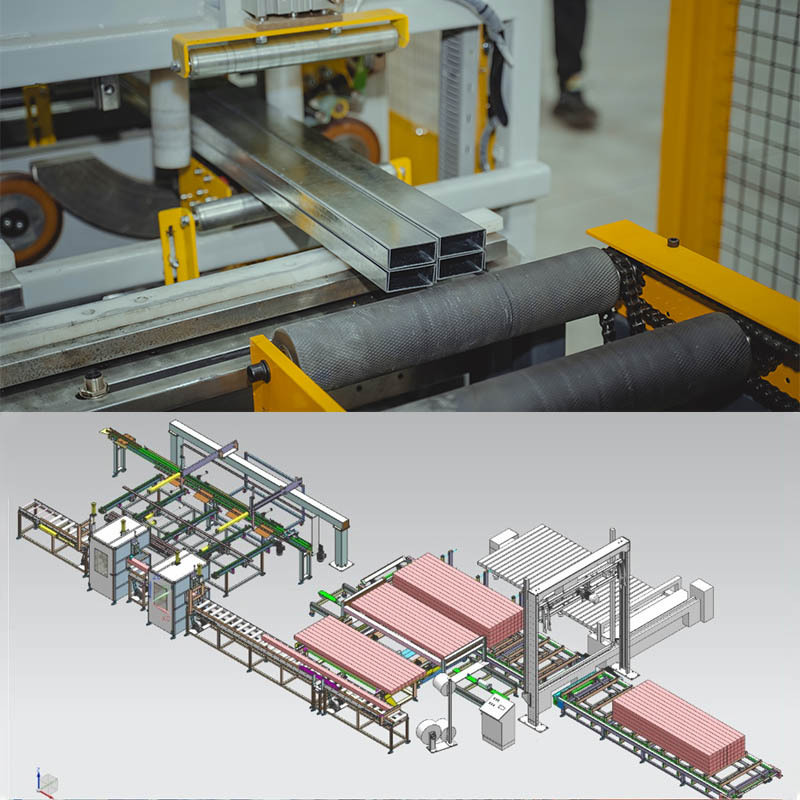

Automatic packing roll forming machine

A packaging roll forming machine is a precision piece of equipment used to produce a wide variety of packaging materials including sheet metal for containers, boxes and other related products. The machine has compact structure, convenient operation and maintenance, and low cost. It adopts advanced technologies such as computer control system and hydraulic cutting system to ensure high precision and high efficiency in the production process. Packaging roll forming machine is composed of uncoiler, feeding system, roll forming system, hydraulic cutting system, control system and so on. The roll forming process is powered by a Programmable Logic Controller (PLC) to provide consistent precision and quality. The hydraulic cutting system ensures smooth and accurate cutting, and the machine can produce different types of metal sheets in different thicknesses, sizes and shapes according to user requirements. Its flexibility makes it suitable for various industrial applications. The high production efficiency and low labor cost of packaging roll forming machines make them a popular choice in the packaging industry.

Packaging roll forming machine is a special equipment used to manufacture various packaging materials. The machine can create different types of packaging solutions including boxes, cartons, trays and other custom designs. The manufacturing process involves the use of different raw materials, such as cardboard, corrugated paper and metal sheets, which are transformed into high-precision and high-quality finished products through computer-controlled technology. The machine's compact design simplifies operation and maintenance, thereby reducing costs. Packaging roll formers are efficient and suitable for both small and large production operations. It provides a cost-effective solution for producing high-quality and precision packaging materials.